How Much is the Tesla Hood Replacement Cost?

The cost of producing an aftermarket hood for a Tesla can vary widely, influenced by several key factors that intertwine to shape the final price. The choice of materials, the manufacturing processes used, labor costs, and overhead expenses all play a significant role. At its core, the production cost includes the raw materials—commonly aluminum or steel—along with costs related to fabrication, assembly, and the necessary quality assurance and testing. Not to mention the ongoing overhead of operating the production facility itself.

However, to provide a more precise cost estimate, a deeper dive into these factors is essential. Market dynamics, supplier pricing, and any specialized features or customizations required for the aftermarket hood all need to be considered. Additionally, economies of scale can greatly affect the per-unit cost, as higher production volumes typically lead to lower costs per unit.

In this article, we’ll break down each element that contributes to the overall manufacturing cost of a Tesla aftermarket hood, and explore how these factors ultimately determine the final price of the product.

1. Tesla Hood Die Mold Development and Production Costs

The development cost of molds for a Tesla hood is shaped by several key factors, each contributing to the final price. These factors include the size and structural complexity of the product, its precise dimensions, the overall shape, and the materials selected for mold casting. Taking the Tesla Model 3 hood as an example, the estimated cost for designing and developing the mold typically ranges from $20,000 to $25,000 USD.

This price reflects the intricate process of creating a mold that meets the high standards required for Tesla parts, factoring in everything from material durability to precision in shaping. The complexity and scale of the mold design play a significant role in determining the development cost, making this a crucial element in the overall production process.

2. Tesla Hood Material Costs

The Tesla Model 3 hood is primarily made from aluminum alloy, with AL5182 being the most common material used for production in the Chinese market. While AL6061, which closely resembles the material used in Tesla’s original factory hoods, is occasionally used, it is much less common.

In China, the cost of AL5182 aluminum alloy is currently between 26,000 and 28,000 RMB per ton, or roughly 26 to 28 RMB per kilogram. Aluminum alloy is used across the hoods of Tesla’s Model 3, Model Y, Model S, and Model X. When disassembling the hood, you’ll find several components, including the outer panel, inner panel, small reinforcement pieces welded to the inner panel, and various screws and rivets.

The full weight of a Tesla Model 3 aluminum hood is around 7.5 kg. With a material utilization rate of about 55%, approximately 13.6 kg of AL5182 is needed for the production of the hood. This translates to a material cost of about 55 USD, or 380 RMB.

3. Tesla Hood Processing Costs

In China, the production of aftermarket automotive parts often relies on simpler mold structures, lacking the advanced mechanization and automation found in Tesla’s original manufacturing processes. This means that a substantial amount of manual labor is needed, from tasks like welding and edging to detailed polishing. In addition, processes such as laser cutting and other forms of post-production processing are essential to finish the parts to the required standards.

Labor costs can vary significantly across different regions of China, but on average, the processing cost for a Model 3 hood is estimated to fall between 50 and 70 RMB, or roughly 10 USD per unit. This cost reflects the labor-intensive nature of aftermarket production, where automation is minimal and manual skill plays a critical role.

4. Coating and Packaging Costs

Before a Tesla hood is shipped, it undergoes an electrophoretic coating process. This treatment serves a dual purpose: it prevents rust and provides an extra layer of protection during the subsequent painting and coloring stages, ultimately extending the hood’s durability. Due to the high volume of automotive parts manufacturers in the region, producing components for top global brands like BMW, Mercedes-Benz, Audi, Volkswagen, and Ford, the cost of electrophoresis remains relatively affordable. For a single hood, the electrophoresis process typically costs between 3 to 4 USD, though regional variations may occur depending on the factory.

Packaging costs, on the other hand, depend on both the materials chosen and the level of protection required. For example, high-quality cardboard, such as 3+2 corrugated cardboard, costs around 1 USD per square meter. Additionally, using thick pearl cotton as internal cushioning increases the packaging cost to approximately 5 USD per hood. These costs ensure that the product is well-protected during shipping, maintaining its quality until it reaches the customer.

Taking all the aforementioned factors into account, the estimated production cost for a Tesla Model 3 hood is approximately 75 USD. With a typical market profit margin ranging from 5% to 10%, the wholesale price from the factory is expected to hover around 80 USD. However, it’s important to remember that fluctuations in raw material prices and the highly competitive nature of the market could cause the price of Tesla’s all-aluminum hoods to drop over time.

Additionally, it’s worth noting that there are hoods currently available on the market for less than 70 USD. If you’re considering purchasing one, be sure to verify that the hood is genuinely made from all-aluminum with a thickness of 1.0mm to ensure you’re getting the quality you expect.

This same method can be applied to estimate the production costs and selling prices of Tesla Model Y, Model S, and Model X hoods in China. By factoring in variables such as hood size, material costs, processing fees, coating, and packaging expenses, we can accurately calculate the production costs and final prices for each model’s hood.

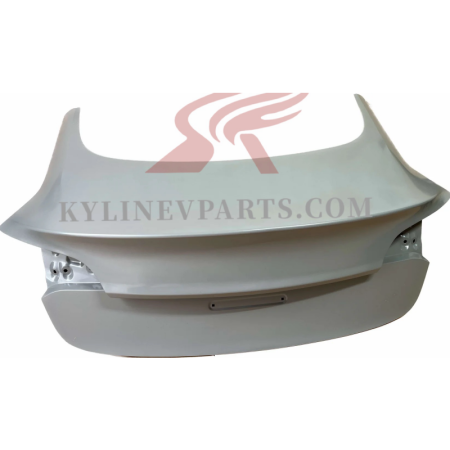

Where to Buy Tesla Hood ?

Kylin EV Parts Ltd is located in Guangzhou, the hub of China’s automotive parts industry. Established in 2013, we focus on the supply chain of new energy automotive parts, providing brand solutions for entire vehicle series from a screw to exterior components, connecting the upstream and downstream supply chains, and forming strategic alliances with production factories through customization, alliance. Adhering to the principle of ensuring the quality of a component is equal to protecting the safety of a family.

In 2022, our international trade department was established, focusing on the integration of Tesla, VW, and BYD, as well as aftermarket modifications. As China’s premier B2B supplier, we offer a comprehensive service in integrating EV spare parts for numerous foreign sellers, both online and offline.

We extend a cordial invitation to collaborate with foreign dealers and explore OEM and ODM partnerships for our products. With our commitment to the most professional service, the highest quality products, and the most reasonable prices, we endeavor to provide unparalleled support.