Which Parts Should Be Cut When Repair Tesla Model 3 Rear Fenders?

Today, we’re diving into two key aspects of the Tesla Model 3: the process of connecting the door pillars and covers, and the intricate procedure involved in cutting the rear fenders. We’ll break down the steps, explore the materials used, and uncover the details that make each task unique. Let’s get started!

Let’s begin by examining the structure of the A, B, and C pillars in vehicles. These pillars are typically composed of either two or three layers of steel plates. In a two-layer configuration, you’ll find one structural component and one cover. In contrast, a three-layer structure consists of two structural components along with a single cover, offering additional strength and support.

The outermost layer, known as the side panel, serves to cover the door pillars. How the structural components are connected to these covers depends largely on the materials used. Steel components are typically joined using spot welding, while aluminum alloy parts are usually attached with self-piercing rivets. In certain vehicles, both methods may be combined to ensure a secure and durable connection.

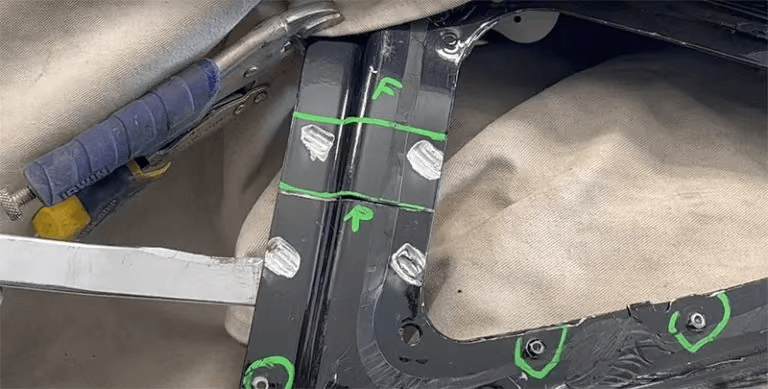

In the Tesla Model 3, the brown-colored sections represent the covers, or side panels. Take note of the polished areas along the edges of the door pillars in the image—these indicate spot welding. On the other hand, the areas that remain unpolished are where self-piercing rivets have been used to secure the components.

The areas where self-piercing rivets are used are marked with red dashed boxes in the image. These rivets are primarily located at the C-pillar and at the bottom of the triangular glass, ensuring a secure connection in these specific regions.

The door pillars of the Tesla Model 3 are connected using two main methods: spot welding, which is the most commonly used technique, and self-piercing riveting. The latter is primarily employed at the C-pillar and the bottom of the triangular glass to ensure a robust and secure connection.

Now that we’ve covered the process of connecting the door pillars, let’s shift our focus to the procedure for cutting the rear fenders. This step requires precision and careful planning to ensure the integrity of the vehicle is maintained.

Examine the structure of the Tesla Model 3’s rear fenders, and you’ll notice an interesting detail: the triangular windows are incorporated into the rear fenders, rather than the rear doors. This design choice plays a significant role in both the aesthetics and functionality of the vehicle.

When you open the trunk of the Tesla Model 3, you’ll notice that the rear edge of the triangular glass aligns perfectly with the rear edge of the trunk lid, creating a smooth and cohesive design.

This alignment defines the critical cutting locations for the rear fenders, with the focus primarily around the triangular glass. These areas are crucial for ensuring precise and effective repairs.

There are two approaches to cutting the rear fenders of the Tesla Model 3: one method involves leaving the rear windshield glass in place, while the other requires removing it. The choice of method usually depends on the extent of the damage to the rear fender and the specifics of the repair needed.

Let’s examine a real example of rear fender cutting on a Tesla Model 3:

Cutting Location 1: Front Portion of the C-pillar Triangular Glass

The image clearly shows the distinction between spot welding and riveting, with the circled points indicating the exact positions of the rivets. This area is critical for ensuring proper alignment during the repair process.

Cutting Location 2: Connection Between the Rear of the Triangular Glass and the Rear Fender Edge

This cutting position does not require the removal of the rear windshield glass, as it is concealed. Due to its hidden nature, it’s difficult to detect any potential issues, making this location particularly challenging to identify during an inspection.

Cutting Location 3: Bottom Edge of the Threshold

This cutting location offers flexibility, as it depends on the severity of the damage and the repair technician’s preferences. It is often favored because it is hidden and unobtrusive, ensuring that the repair remains discreet and doesn’t compromise the vehicle’s appearance.

Finally, let’s look at the most common cutting method used for the Tesla Model 3’s rear fenders.

Due to the distinctive structure of the rear fenders, the cutting process is subtle, making it challenging to identify without prior expertise. On top of that, the two different connection methods employed for the door pillars add an additional layer of complexity, further complicating the identification process. This combination of factors requires a keen eye and a deep understanding of the vehicle’s design to properly assess the repairs.

In this article, we delved into the intricate process of repairing the Tesla Model 3’s rear fenders, pinpointing the key areas that need to be cut during the repair. We emphasized the crucial role of precision and meticulous planning to ensure that the repair not only restores functionality but also preserves the vehicle’s structural integrity.

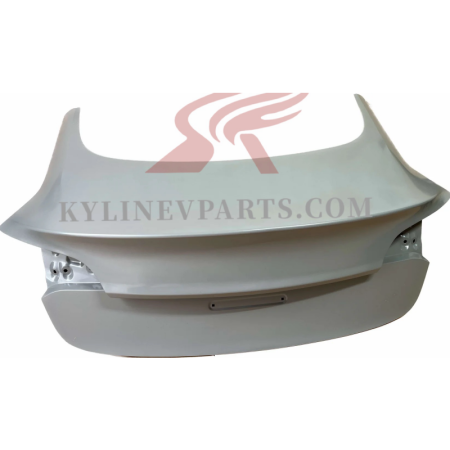

Where to Buy Tesla Parts and Accessories ?

Kylin EV Parts Ltd is located in Guangzhou, the hub of China’s automotive parts industry. Established in 2013, we focus on the supply chain of new energy automotive parts, providing brand solutions for entire vehicle series from a screw to exterior components, connecting the upstream and downstream supply chains, and forming strategic alliances with production factories through customization, alliance. Adhering to the principle of ensuring the quality of a component is equal to protecting the safety of a family.

In 2022, our international trade department was established, focusing on the integration of Tesla, VW, and BYD, as well as aftermarket modifications. As China’s premier B2B supplier, we offer a comprehensive service in integrating EV spare parts for numerous foreign sellers, both online and offline.

We extend a cordial invitation to collaborate with foreign dealers and explore OEM and ODM partnerships for our products. With our commitment to the most professional service, the highest quality products, and the most reasonable prices, we endeavor to provide unparalleled support.