Is Tesla Hood Aluminum?

The bonnet of the Tesla Model 3, Y, X, and S is made from AL6061 aluminum alloy—a material that perfectly aligns with Tesla’s commitment to innovation. Aluminum is a staple in Tesla’s design and is favored for its lightness compared to steel. This key characteristic not only reduces the vehicle’s weight but also significantly boosts its range, performance, and overall efficiency. By choosing this high-strength, low-weight alloy, Tesla ensures that every aspect of their electric vehicles (EVs) is fine-tuned for maximum performance. It’s a clear testament to their engineering philosophy: prioritize cutting-edge technology to achieve the best in performance and energy efficiency.

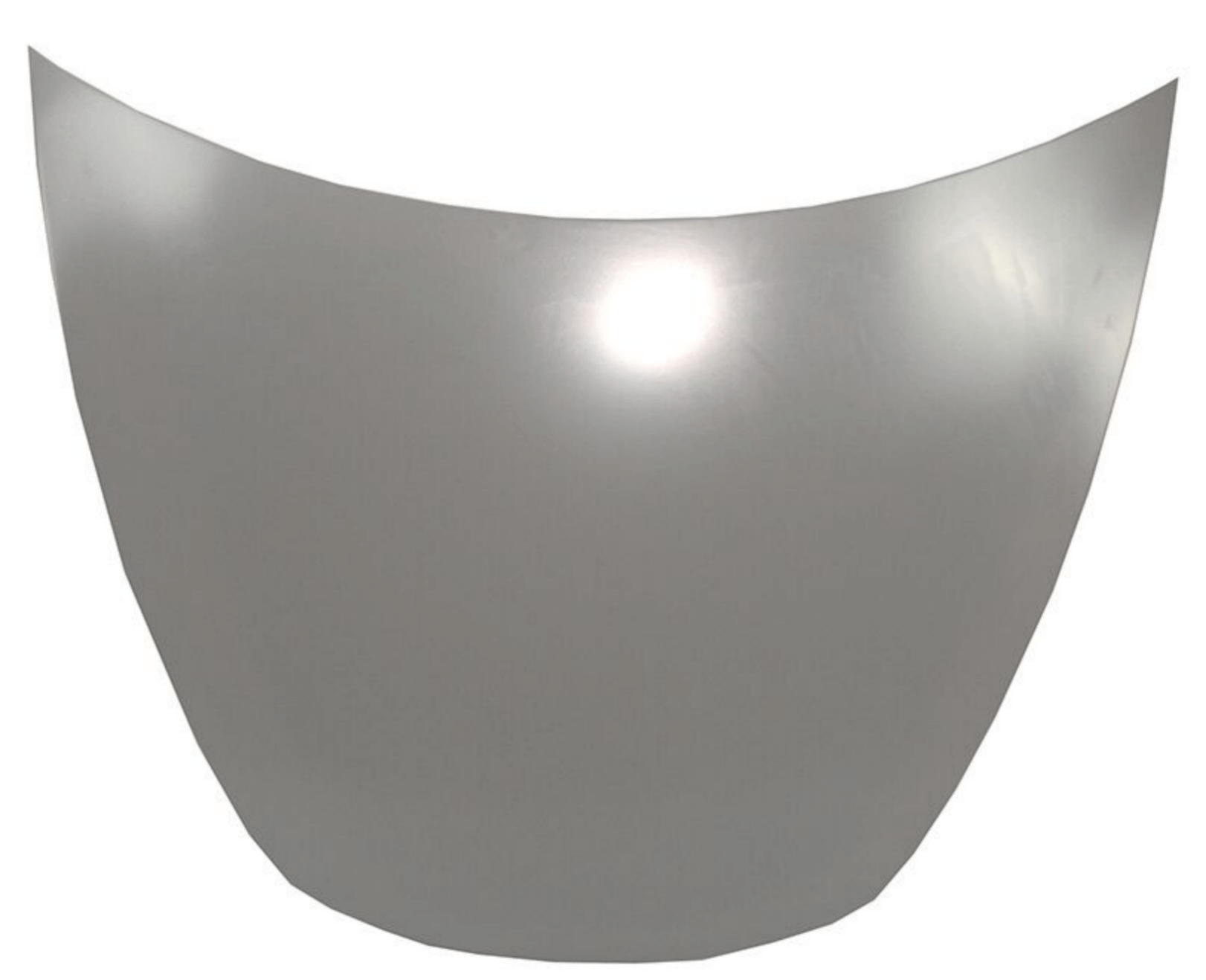

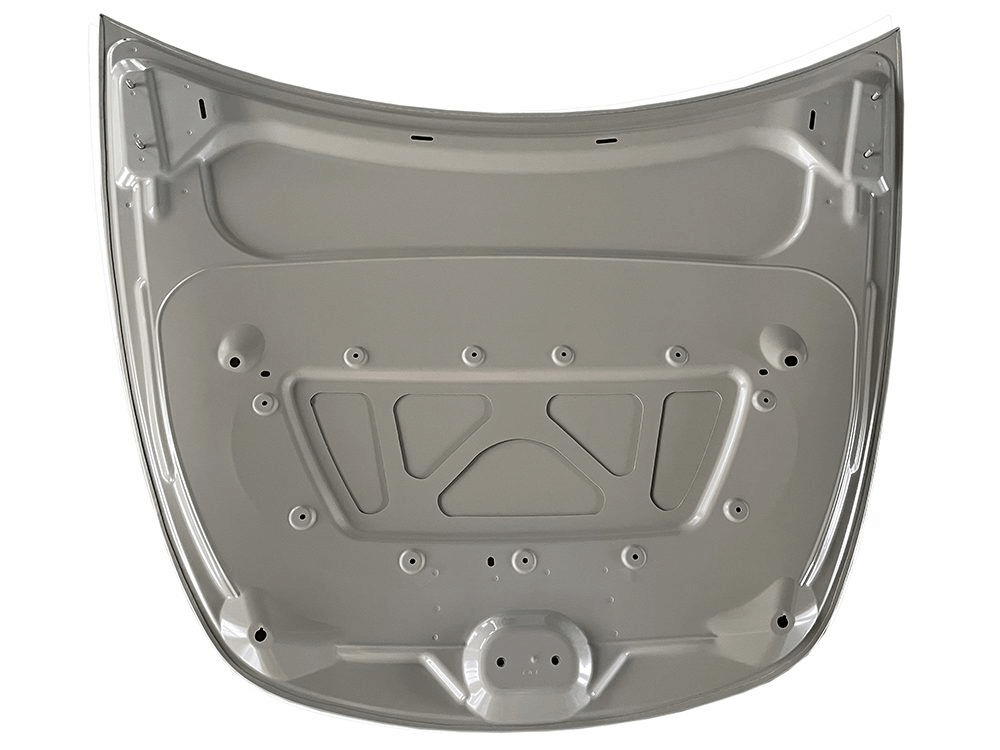

Tesla Model 3 Hood High Version Full Aluminum 1081390E0C 1081390-E0-C

AL6061 aluminum, also known as 6061-T6, is a remarkably versatile alloy, primarily composed of aluminum, magnesium, and silicon. As part of the 6000 series, it stands out for its excellent strength-to-weight ratio, impressive corrosion resistance, and excellent weldability. These characteristics make it an ideal choice for industries that require a delicate balance of strength and lightness—whether in aerospace, automotive, or other high-performance applications. Its ability to withstand harsh environments while remaining lightweight and durable is what makes AL6061 so widely sought after.

Characteristics and Properties of AL6061 Aluminum Alloy:

- Strength: AL6061 aluminum boasts excellent strength, making it perfect for structural applications that require both durability and long-lasting reliability.

- Machinability: This alloy excels in machinability, meaning it can be easily cut, drilled, and shaped with precision. This makes it ideal for streamlining the manufacturing process.

- Weldability: AL6061 is highly weldable, whether through TIG, MIG, or arc welding methods. Its versatility in welding makes it an excellent option for creating intricate and complex parts.

- Corrosion Resistance: The alloy is known for its strong resistance to corrosion, particularly in environments with moderate moisture and exposure to various chemicals, contributing to its durability over time.

- Heat Treatment: AL6061 can undergo heat treatment to enhance its mechanical properties, such as boosting strength and hardness. This adaptability further broadens its range of applications.

- Applications: With its unique blend of strength, machinability, and corrosion resistance, AL6061 is commonly used in industries like aerospace, automotive, marine, and construction. Additionally, it is widely used in manufacturing products such as bicycle frames, firearm components, and consumer electronics.

Aftermarket Tesla Hood Made from AL5182 Aluminum

Our aftermarket Tesla hoods are constructed from AL5182 aluminum alloy, a material known for its superior quality and high hardness. This alloy meets stringent automotive-grade standards, ensuring both outstanding performance and long-lasting durability. Unlike the more commonly used AL6061, which isn’t typically found in factory hoods, AL5182 is specifically selected for its impressive strength and resilience. It’s worth noting that variations in material thickness can impact both the quality and cost of the product. In some instances, manufacturers may even use iron for Tesla hoods, but this compromises performance and longevity, making AL5182 the more reliable choice.

What is AL5182?

AL5182 is an aluminum alloy composed mainly of aluminum, magnesium, and manganese. It belongs to the 5000 series of aluminum alloys, which are renowned for their moderate-to-high strength, exceptional corrosion resistance, and good weldability. These qualities make AL5182 a trusted choice for applications that demand both durability and resistance to environmental elements, making it particularly valuable in industries such as marine and automotive, where exposure to harsh conditions is common.

Characteristics and Properties of AL5182 Aluminum Alloy:

- Strength: AL5182 delivers strong performance, making it ideal for structural applications that require both resilience and long-term durability.

- Corrosion Resistance: This alloy is highly resistant to corrosion, particularly in marine and saltwater environments. It also performs exceptionally well against atmospheric corrosion and many industrial chemicals, ensuring durability even in harsh conditions.

- Formability: AL5182 stands out for its excellent formability. It can be easily shaped, stamped, and drawn into intricate parts and components without sacrificing strength.

- Weldability: AL5182 is highly weldable using various techniques such as MIG, TIG, and resistance welding. It poses minimal risk of cracking or distortion during welding, making it suitable for complex assemblies.

- Surface Finish: The alloy can be effectively finished through processes like anodizing, painting, or powder coating, improving both its aesthetic qualities and its resistance to corrosion.

- Applications: Thanks to its blend of strength, corrosion resistance, and formability, AL5182 is widely used in automotive applications like body panels, hoods, and roofs. It is also commonly used in the manufacturing of beverage can lids, truck trailers, and marine components.

| Property | AL5182 Aluminum Alloy | AL6061 Aluminum Alloy |

| Composition | Aluminum, Magnesium, Manganese | Aluminum, Magnesium, Silicon |

| Series | 5000 Series | 6000 Series |

| Strength | Moderate | High |

| Corrosion Resistance | Excellent | Good |

| Formability | Good | Excellent |

| Weldability | Good | Excellent |

| Heat Treatment | Not Typically Heat Treatable | Heat Treatable |

| Typical Applications | Automotive Body Panels, Beverage Can Lids, Marine Components | Structural Components, Automotive Parts, Aerospace Components |

How to Obtain an Aftermarket Tesla Aluminum Alloy Hood

To acquire an aftermarket Tesla hood, your best approach is to connect with reputable suppliers in China. With its well-established industrial network, China is home to 90% of Tesla’s component sourcing. Here, you’ll find a wide range of manufacturers providing high-quality parts, including hoods made from premium aluminum alloys. We are based in China and specialize in helping customers source top-tier Tesla sheet metal components. Let us guide you in finding the perfect solution for your needs.

Where to Buy Tesla Hood Aluminum?

Kylin EV Parts Ltd is located in Guangzhou, the hub of China’s automotive parts industry. Established in 2013, we focus on the supply chain of new energy automotive parts, providing brand solutions for entire vehicle series from a screw to exterior components, connecting the upstream and downstream supply chains, and forming strategic alliances with production factories through customization, alliance. Adhering to the principle of ensuring the quality of a component is equal to protecting the safety of a family.

In 2022, our international trade department was established, focusing on the integration of Tesla, VW, and BYD, as well as aftermarket modifications. As China’s premier B2B supplier, we offer a comprehensive service in integrating EV spare parts for numerous foreign sellers, both online and offline.

We extend a cordial invitation to collaborate with foreign dealers and explore OEM and ODM partnerships for our products. With our commitment to the most professional service, the highest quality products, and the most reasonable prices, we endeavor to provide unparalleled support.