Tesla EV Parts: A B2B Buying Guide That Prevents Fitment Failures

The fastest way to lose money in Tesla EV parts is not paying too much. It’s selling the right-looking part that doesn’t actually fit. In Tesla EV parts, the same part name can hide multiple revisions, connectors, standards, and LHD/RHD differences. If your fitment process is weak, returns and disputes will eat your margin alive. That’s why this Tesla EV parts guide starts with a practical fitment workflow you can run today, then moves into a category map to help you scale from fast-moving Tesla EV parts SKUs to high-margin Tesla EV parts repair lines.

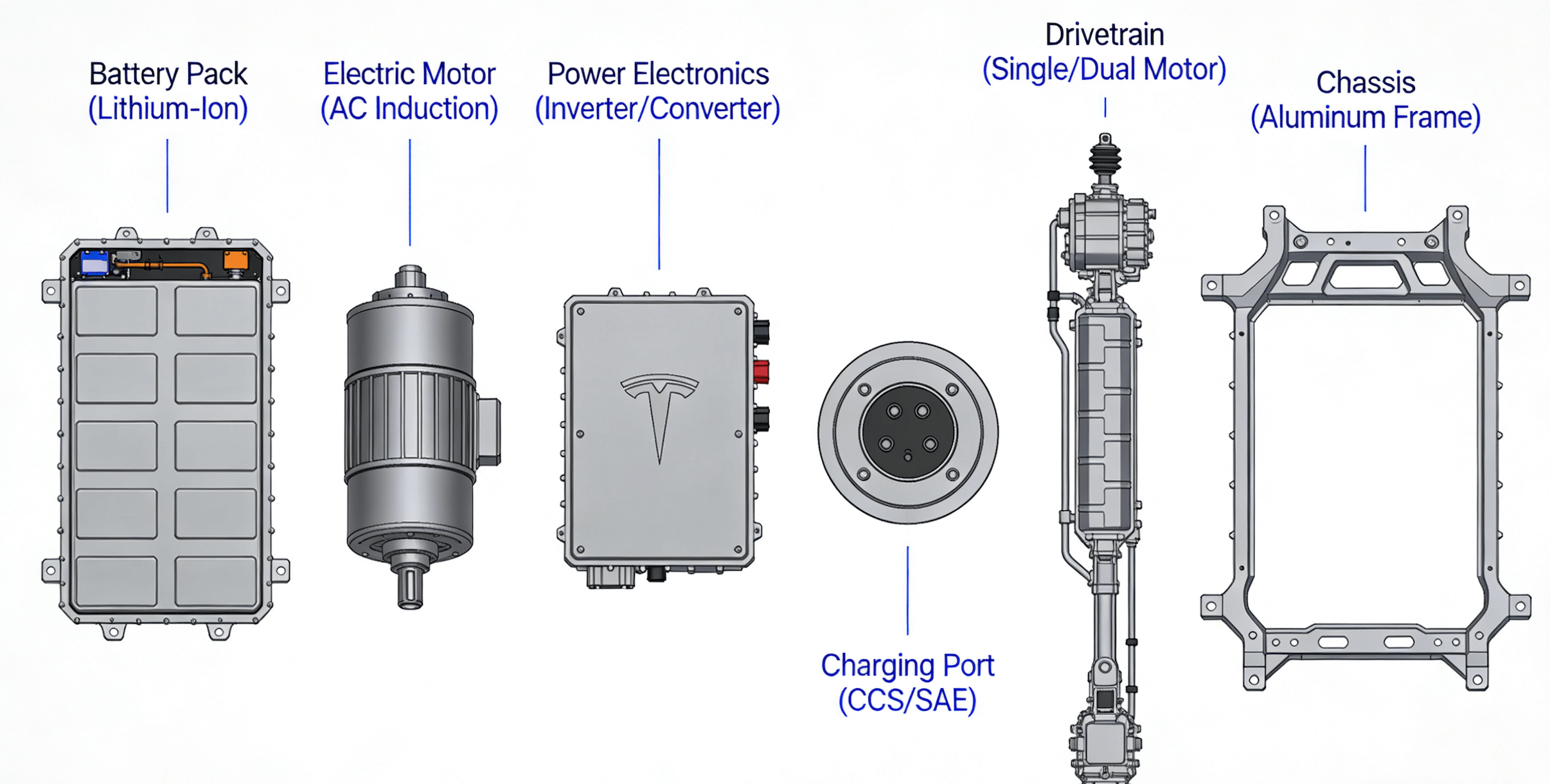

The Three Demand Buckets in Tesla EV Parts

In Tesla EV parts, B2B demand typically falls into three buckets. Understanding these buckets helps you choose the right categories, build the right pricing ladder, and avoid the wrong risks at the wrong time.

1) Fast-moving consumables

These are high-frequency, lower-ticket parts that are easy to start with. Think cabin filters, wipers, and other maintenance-related items. The main value of these SKUs is not a huge margin. It’s order frequency and cooperation rhythm. If you want repeat orders, these products make your pipeline predictable.

2) Repair-critical functional parts

These parts are higher ticket and higher margin, but fitment and liability boundaries matter a lot. This bucket includes electronics-heavy items, HVAC-related components, suspension and steering parts, and many lighting assemblies. These are where you can make money or lose money quickly, depending on how strict your fitment workflow is.

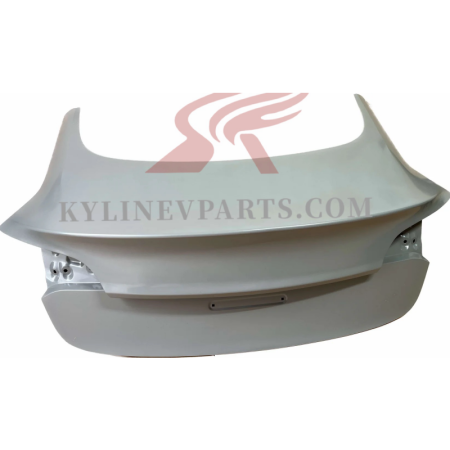

3) Collision and body parts

These are bulky and logistics-heavy. Packaging discipline determines scalability. It’s not just about sourcing. It’s about whether your operation can keep damage rates low, keep labeling clean, and keep warehouse handling friction under control.

A practical growth path is often: use consumables to build ordering rhythm, use repair parts to earn margin, and use collision lines to deepen customer stickiness.

Why Fitment Becomes the Margin Black Hole

In legacy ICE parts, many orders can be validated with model + year + engine. In Tesla EV parts, that shortcut breaks. If you want to survive as a distributor or a repair-network supplier, you need to accept the structural reasons:

- Rapid revisions, sometimes multiple variants within the same model year

- Part-number supersessions and mid-cycle supplier changes

- Regional standard differences (ECE vs SAE) that impact compatibility

- Electronics dependence: many parts depend on software, sensors, harness connectors, and calibration context

So in B2B, you’re not really selling parts. You’re selling certainty. And certainty comes from a repeatable, enforceable fitment workflow.

A Practical B2B Fitment Verification Workflow for Tesla EV Parts

Treat the following fitment workflow as your non-negotiable quotation and purchasing rule for Tesla EV parts. When executed consistently, it reduces returns and disputes dramatically.

Step 1: Collect more than just a part number

In Tesla EV parts, you need at least two of the following before you quote confidently:

- VIN or official vehicle registration details

- Model/year/revision (for example, Model 3 2021 vs Model 3 Highland)

- LHD or RHD

- Regional standard (ECE vs SAE)

- Photos of the original part (installed or removed)

- Symptom description and repair reason

If you’re quoting with only a part name and a vague description, you’re not quoting. You’re gambling.

Step 2: Flag high-risk categories before quoting

High-risk parts typically include:

- Headlamp assemblies, sensors, cameras, and radar-related components

- HVAC components, electronic modules, and harnesses

- Suspension, steering, chassis parts

- Anything with connectors, calibration requirements, or left/right variants

Lower-risk parts typically include:

- Wipers, cabin filters, trim pieces, standard consumables

A simple rule: if an item has connectors, software context, left/right variants, or critical safety implications, treat it as high-risk and slow down your quotation process.

Step 3: Use triple verification to prevent fitment failure

Verification A: Start with the part number, but don’t end there. Part numbers are helpful, but not always the final truth due to revisions and supersessions.

Verification B: Confirm the connector and physical details. Check pin layout, bracket points, harness length, mounting positions, and any visible revision clues.

Verification C: Require photo confirmation or photo matching against the original part. For high-risk items, you should treat photos as mandatory. Photos reduce misunderstandings more than any email paragraph ever will.

Step 4: Put liability boundaries inside your quotation

For Tesla EV parts, always state clearly:

- Fitment is verified based on customer-provided information

- Without VIN or key photos, pricing is provisional and requires secondary confirmation

- Some electronic items may require professional tools and calibration

- Return policy conditions and exceptions

This is not about scaring buyers. This is how you protect both sides from endless blame loops.

Choosing Supply Channels: Don’t Worship a Single Answer

Think of sourcing as three parallel lines. Most B2B buyers who win use more than one line, depending on category and urgency.

Official channels

Official channels can be useful for personal repair or urgent single items, but they’re often difficult to scale for distributors because of limitations in consistency, pricing structure, and availability. For B2B distribution, relying only on official channels usually creates supply instability.

High-quality aftermarket and branded service parts

This is the real B2B battlefield. The winning edge is not the loudest marketing. It’s consistency and traceability. If your supply is stable, your customer’s planning becomes stable, and planning stability is a product in itself.

Used and recycled parts

Used inventory can be a margin pool, but only if you run grading standards, condition records, and clear traceability. “Used” must be operationally defined: what you accept, what you refuse, how you document, and how you handle disputes.

In B2B, the best channel is not the one that sounds premium. The best channel is the one that delivers a stable supply, a predictable lead time, consistent quality, clear return rules, and a repeatable pricing ladder.

Category Map in Tesla EV Parts: From Fast-Moving SKUs to High-Margin Lines

Here’s a practical category map designed for distributors and repair networks. If you follow this map, you avoid many expensive detours.

1) Fast-moving repeat items: build ordering rhythm first

Cabin filters, wipers, charging-related small items, interior small parts, and maintenance consumables are classic starters. Their main value is order frequency. Use these SKUs to establish replenishment rhythm, reconciliation habits, and communication efficiency.

Once stable, expand your mix into higher-margin repair lines. A lot of B2B friction disappears when both sides already have a working ordering rhythm.

2) High-margin repair parts: the real skill is risk control

Margin often concentrates in these zones:

- Suspension, steering, and chassis-related parts

- HVAC-related components

- Lighting and electrical assemblies

Within these categories, some items become “stable demand but unstable supply” opportunities. If you can supply those consistently, you become the default vendor in the buyer’s mind. Being default is worth more than being the cheapest.

Your best move is to build a small portfolio of high-margin items where you can offer consistent revisions, consistent packaging, and consistent dispute handling.

3) Collision and body parts: your moat is logistics discipline

Body parts are not hard because of pricing. They’re hard because of packaging, labeling, volumetric weight, damage-rate control, and downstream handling workflows.

If you want to scale collision lines, you must standardize:

- Packaging standards (edge protection, anti-scratch, structural reinforcement)

- Labeling and sorting for warehouses

- Documentation for receiving and damage claims

- Re-boxing and downstream handling workflows

When you standardize these, buyers prefer you because you reduce operational headaches.

Common Quality Issues Seen in the Repair Market for Tesla EV Parts

If you supply B2B distributors or repair networks, you must talk about quality issues inTesla EV parts directly. Not to talk down the market, but to define standards, align expectations, and reduce return disputes. The following are common, highly controversial quality issues frequently seen in repair markets. You can convert them into inspection standards and quotation clauses.

1) Headlamp condensation or water ingress after rain that does not clear

Common dispute triggers: buyers assume defective sealing or assembly failure. Root causes can involve vent membranes, valves, sealing compound, assembly tolerance, or process control.

B2B handling recommendations:

- Require evidence of sealing and aging tests from suppliers

- On arrival, spot-check seam lines, sealant continuity, and vent structures

- State usage and installation requirements in your terms, plus clear criteria for what counts as a defect

2) Scratches or rough finishing on plastic exterior parts

Examples: bumper covers, lower undertrays, trim strips. Cosmetic defects lead to rejection or post-install complaints about finishing quality.

B2B handling recommendations:

- Define an appearance AQL standard and what is acceptable

- Require anti-scratch protective film and corner protection in packaging

- Grade high-complaint SKUs into quality tiers, clearly separating premium vs competitive versions

3) Wheel paint defects

Including peeling or uneven coating. Surface finishing is highly sensitive; buyers rarely tolerate visible defects.

B2B handling recommendations:

- Request coating process details and adhesion test evidence

- Add gloss and coverage checks into arrival inspection

- Packaging must prevent abrasion, and your terms should define how to distinguish transport damage vs process defects

4) Hub cap color mismatch vs OEM

Even if functional, color deviation impacts vehicle appearance and triggers returns.

B2B handling recommendations:

- Request color swatch references and batch color management

- Define acceptable color tolerance between batches

- State color version and batch consistency requirements clearly in the quotation and PO

5) Door or fender gaps too large, still excessive after adjustment

Panel alignment is a high-risk area. After installation, uneven gaps are often treated as unacceptable geometry accuracy.

B2B handling recommendations:

- Require dimensional gauges or key measurement points from suppliers

- If possible, recommend pre-shipment test-fit or provide key measurement records

- For these high-risk items, terms must state fitment prerequisites and installation conditions, and require before/after photos for dispute handling

This section matters because it turns “quality complaints” into operational standards. In Tesla EV parts, operational standards are what protect your margin.

You’re Building a Repeatable B2B Model, Not a One-Off Deal

A stable B2B model in Tesla EV parts often looks like this:

- Start with a fast-moving hot list to create repeat orders

- Use a strict fitment workflow to lower return rates

- Build a pricing ladder that encourages consistent replenishment

- Define warranty and return boundaries to minimize dispute costs

- Expand into high-margin repair and collision lines to deepen customer stickiness

The core is simple: turn uncertainty into process, turn process into standards, and turn standards into scalable growth.

How We Support Distributors and Repair Networks in Tesla EV Parts

If you’re running B2B procurement in Tesla EV parts, you rarely need fancy promises. You need three practical assets:

- A usable hot-selling list

- A verifiable fitment workflow

- A workable replenishment and delivery rhythm

Our approach at Kylin EV Parts is built around that reality. We focus on Tesla EV parts for B2B supply with aftermarket and used coverage, and we help buyers start faster with a curated hot list. We can also show stock and revision details via video verification, and we typically recommend beginning with low-risk, high-repeat SKUs so you can stabilize the model before expanding into higher-margin repair lines.

What Makes Tesla EV Parts a Long-Term Business

In the long run, Tesla EV parts are not won by sharper sales talk. It’s won by the operator who turns fitment, delivery, and after-sales boundaries into standards. When you deliver consistently, control risk, and make pricing predictable, buyers reorder. That’s the real moat in B2B.

If you want to move faster, ask us for a practical hot-selling list, plus fitment checkpoints, quality tier suggestions, and ready-to-use return policy boundaries. You can contact Jamie directly. Kylin EV Parts is a reliable long-term Tesla EV parts supplier with strong coverage in the aftermarket and used demand. With the list in hand, you can start procurement planning and market testing immediately, without guessing from scratch.