Tesla’s Global Manufacturing Footprint

Tesla, Inc., renowned for its innovative approach to electric vehicles and sustainable energy solutions, has established a formidable global manufacturing network. This network is pivotal in meeting the growing demand for its products and advancing its mission to accelerate the world’s transition to sustainable energy. Let’s explore Tesla’s major manufacturing facilities and understand where and how Tesla’s parts are produced.

Where Are Tesla’s Major Manufacturing Facilities Located?

Tesla operates several key manufacturing facilities across the globe, each contributing uniquely to its production capabilities:

Tesla Gigafactory 1 (Nevada, USA)

- Overview: Located in Sparks, Nevada, Gigafactory 1 is Tesla’s flagship battery and electric vehicle (EV) production facility. Officially opened in 2016, it plays a crucial role in producing lithium-ion batteries and electric powertrains.

- Production Focus: This facility is primarily responsible for manufacturing battery packs and drive units for Tesla’s vehicles. It also focuses on scaling up the production of battery cells to meet the increasing demand for Tesla’s EVs. Learn more about Gigafactory

Tesla Gigafactory 2 (New York, USA)

- Overview: Situated in Buffalo, New York, Gigafactory 2 is dedicated to solar products and energy storage solutions. Opened in 2017, it represents Tesla’s push into renewable energy.

- Production Focus: This facility focuses on manufacturing solar panels and Solar Roof tiles, as well as energy storage products like the Powerwall and Powerpack. Discover Gigafactory 2.

Tesla Gigafactory 3 (Shanghai, China)

- Overview: Tesla’s first Gigafactory outside the United States, located in Shanghai, China, began operations in late 2019. This facility is crucial for Tesla’s expansion into the Asian market.

- Production Focus: Gigafactory 3 is responsible for producing the Model 3 and Model Y vehicles specifically for the Chinese market, significantly reducing shipping costs and delivery times for customers in Asia. Explore Gigafactory 3.

Tesla Gigafactory 4 (Berlin, Germany)

- Overview: Also known as Giga Berlin, this facility is Tesla’s European manufacturing hub. Officially opened in 2022, it aims to bolster Tesla’s presence in Europe.

- Production Focus: Gigafactory 4 focuses on producing the Model Y and future Tesla models for the European market, enhancing Tesla’s ability to meet local demand and streamline logistics. Learn about Giga Berlin.

Tesla Gigafactory 5 (Austin, Texas, USA)

- Overview: Located in Austin, Texas, this state-of-the-art facility is the newest addition to Tesla’s manufacturing network, inaugurated in 2024. It represents a significant investment in production capacity.

- Production Focus: Gigafactory 5 will focus on manufacturing the Cybertruck, Semi, and battery cells, alongside vehicle assembly and battery production. This facility is expected to play a key role in meeting the demands of Tesla’s expanding product lineup. Find out more about Gigafactory 5.

What Parts Are Produced at Each Facility?

Each Tesla Gigafactory has a specialized focus, contributing to a diverse range of products:

- Battery Packs and Drive Units: Produced mainly at Gigafactory 1, these components are essential for Tesla’s electric vehicles, providing the energy and propulsion systems necessary for high performance.

- Vehicle Assemblies: Gigafactories 1, 3, 4, and 5 handle various stages of vehicle assembly, from components to finished models. Gigafactory 3 focuses on the Model 3 and Model Y, while Gigafactory 4 and Gigafactory 5 contribute to European and North American markets, respectively.

- Energy Products: Gigafactory 2 specializes in solar and energy storage products, producing items like solar panels and the Powerwall, which are integral to Tesla’s clean energy solutions.

Tesla’s global manufacturing footprint is a testament to its commitment to innovation and sustainability. By strategically locating its Gigafactories around the world, Tesla not only meets the local demand for its products but also optimizes its supply chain and production processes. This global network allows Tesla to stay ahead in the competitive automotive and energy markets, reinforcing its role as a leader in sustainable technology.

US-Based Manufacturing

Tesla’s manufacturing strategy in the United States is central to its operations, reflecting the company’s commitment to innovation, quality, and sustainability. By leveraging domestic production capabilities, Tesla not only supports its robust supply chain but also enhances its ability to deliver high-quality electric vehicles (EVs) and energy products to customers. Here, we explore which Tesla parts are manufactured in the US, the impact of this domestic production on the company’s supply chain and costs, and the benefits of keeping manufacturing operations within the United States.

Which Tesla Parts Are Manufactured in the US?

Tesla’s US-based facilities are pivotal in the production of several key components and products:

Battery Packs and Drive Units:

- Overview: At Gigafactory 1 in Nevada, Tesla manufactures battery packs and drive units, which are essential for its range of electric vehicles. This facility is designed to significantly increase the production of lithium-ion battery cells, which are integral to Tesla’s EVs. The scale and efficiency of Gigafactory 1 contribute to lowering costs and improving battery performance. Learn more about Tesla’s battery production.

Vehicle Assembly:

- Overview: Tesla’s main assembly operations for several vehicle models, including the Model S, Model X, and the new Cybertruck, are carried out at various US facilities. Gigafactory 5 in Austin, Texas, plays a significant role in the assembly of the Cybertruck and the Tesla Semi, reflecting the facility’s cutting-edge production capabilities. Explore the latest from Gigafactory 5.

Energy Products:

- Overview: Gigafactory 2 in Buffalo, New York, focuses on manufacturing solar products and energy storage solutions. This facility produces Solar Roof tiles and Powerwall batteries, which are essential components of Tesla’s clean energy ecosystem. Discover Tesla’s energy solutions.

Impact of US Manufacturing on Tesla’s Supply Chain and Production Costs

Manufacturing in the US has several implications for Tesla’s supply chain and overall production costs:

Logistics and Transportation:

- Impact: Domestic manufacturing reduces shipping times and transportation costs associated with moving parts and finished products. By producing vehicles and components closer to major markets, Tesla can streamline its logistics and improve delivery efficiency. This is especially beneficial in managing supply chain disruptions and meeting customer demand promptly. Read more about Tesla’s supply chain management.

Cost Implications:

- Labor and Material Costs: While manufacturing in the US involves higher labor costs compared to some international locations, the company benefits from reduced shipping expenses and avoids tariffs on imported goods. Additionally, investments in advanced manufacturing technologies help offset these costs by increasing efficiency and productivity. Learn about the economics of US manufacturing.

Quality Control:

- Benefits: Keeping manufacturing within the US allows Tesla to maintain strict quality control standards and ensure consistent product quality. Local production facilities enable closer monitoring of manufacturing processes and quicker response to any issues that arise, thereby enhancing product reliability and customer satisfaction. Explore Tesla’s quality control practices.

Benefits of Manufacturing Parts in the US

Manufacturing parts and products domestically offers several advantages for Tesla:

Reduced Shipping Times:

- Advantage: By producing goods closer to where they are sold, Tesla minimizes delivery times and shipping costs. This efficiency is particularly crucial for high-demand products and contributes to a better customer experience.

Tariff and Trade Considerations:

- Advantage: Domestic manufacturing helps Tesla avoid tariffs and trade restrictions that can affect international shipments. This strategic advantage reduces costs and simplifies compliance with trade regulations. Read about the impact of tariffs on manufacturing.

Regulatory Compliance:

- Advantage: Manufacturing in the US ensures adherence to local regulatory standards and environmental regulations. This compliance supports Tesla’s commitment to sustainability and corporate responsibility, aligning with its mission to promote clean energy. Discover Tesla’s sustainability efforts.

Tesla’s US-based manufacturing facilities are central to its strategy for producing high-quality electric vehicles and energy products. By maintaining robust domestic operations, Tesla benefits from improved logistics, cost efficiency, and quality control, while also aligning with regulatory and sustainability goals. As Tesla continues to innovate and expand, its commitment to US manufacturing remains a cornerstone of its global success.

International Manufacturing and Sourcing

Tesla’s global manufacturing strategy extends well beyond its US-based facilities, incorporating significant international production and sourcing elements. This international footprint is crucial for meeting the growing demand for Tesla vehicles and energy products worldwide. Here, we delve into which Tesla parts are sourced internationally, the effects of this global manufacturing approach, and the key countries involved.

Which Tesla Parts Are Sourced Internationally?

Tesla’s international manufacturing and sourcing strategy involves several key components:

Battery Materials:

- Lithium and Cobalt: Essential for battery production, lithium, and cobalt are sourced from various international suppliers. Major suppliers include companies in Australia, Chile, and the Democratic Republic of Congo. These materials are critical for Tesla’s battery packs, which power its electric vehicles (EVs). Read more about Tesla’s battery supply chain.

- Graphite: Used in battery anodes, graphite is another vital material sourced from international suppliers, including those in China and Canada.

Vehicle Components:

- Microcontrollers and Semiconductors: Many of Tesla’s electronic components, such as microcontrollers and semiconductors, are sourced from suppliers in Asia, particularly Taiwan and South Korea. These components are integral to Tesla’s advanced driver-assistance systems (ADAS) and in-car electronics. Explore Tesla’s tech innovations.

Assembly Parts:

- Manufacturing in China: At Gigafactory 3 in Shanghai, Tesla produces the Model 3 and Model Y for the Asian market. Parts for these vehicles are sourced both locally and from international suppliers to streamline production and reduce costs. Learn about Gigafactory 3.

- European Components: Gigafactory 4 in Berlin sources parts from various European suppliers to support the production of Model Y and future models for the European market. Read about Gigafactory 4.

Effects of International Manufacturing on Tesla’s Operations

Tesla’s international manufacturing and sourcing strategy has several significant effects:

Complexity and Risk Management:

- Supply Chain Complexity: Managing a global supply chain introduces complexities, such as coordinating across different time zones and dealing with varying regulatory requirements. Tesla addresses these challenges by employing sophisticated logistics and supply chain management systems.

- Geopolitical Risks: International manufacturing exposes Tesla to risks such as trade tensions and political instability. For instance, tariffs and trade restrictions can impact the cost and availability of materials. Read about geopolitical impacts on global supply chains.

Cost Considerations:

- Production Costs: International manufacturing can reduce costs through economies of scale and access to lower-cost materials or labor. For example, manufacturing in Shanghai and Berlin allows Tesla to avoid import duties and shipping costs for these key markets.

- Logistics Efficiency: By locating production facilities closer to major markets, Tesla reduces shipping times and costs, improving overall logistics efficiency. Explore Tesla’s supply chain strategies.

Key Countries Involved in Tesla’s International Manufacturing

Several countries play a pivotal role in Tesla’s international manufacturing and sourcing:

China:

- Role: As a major hub for Tesla’s Asian operations, China provides critical manufacturing capabilities at Gigafactory 3 in Shanghai. The country is also a key supplier of various components and materials. Discover Tesla’s impact in China.

Germany:

- Role: Germany hosts Gigafactory 4 in Berlin, which is essential for meeting European demand. The facility sources parts from local and international suppliers to support its production. Learn about Tesla’s operations in Germany.

South Korea and Japan:

- Role: These countries are major suppliers of high-tech components like semiconductors and battery materials. They play a crucial role in ensuring Tesla’s vehicles and energy products incorporate advanced technology. Explore technology contributions from South Korea and Japan and Japan’s role in tech supply chains.

Tesla’s international manufacturing and sourcing strategy is fundamental to its global success. By leveraging global production capabilities and sourcing key materials from around the world, Tesla not only meets the diverse demands of its international markets but also optimizes its supply chain efficiency. This approach positions Tesla well for continued growth and innovation in the competitive electric vehicle and renewable energy sectors.

Comparative Analysis

Understanding Tesla’s manufacturing strategy requires examining how it compares to other automotive manufacturers and identifying broader trends in global sourcing and local production. This comparative analysis highlights Tesla’s distinctive approach within the industry and sheds light on emerging patterns that are shaping the future of automotive manufacturing.

How Does Tesla’s Manufacturing Strategy Compare to Other Automotive Manufacturers?

Tesla’s manufacturing approach stands out in several ways when compared to traditional automotive manufacturers:

Domestic vs. International Production:

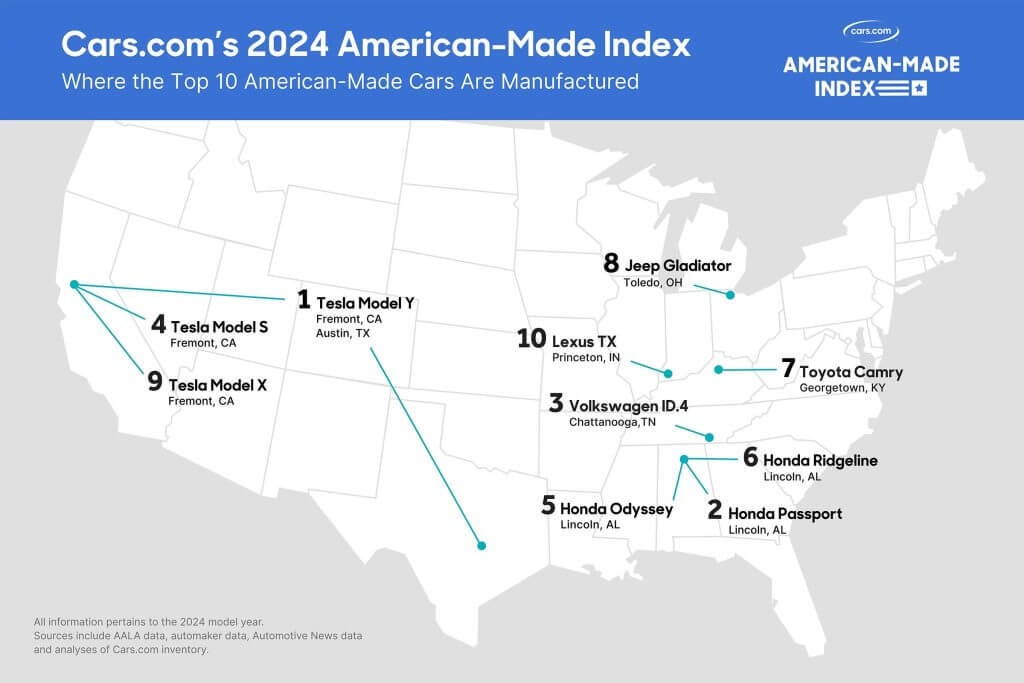

- Tesla: Tesla’s strategy integrates both domestic and international production to balance cost, efficiency, and market demand. The company’s Gigafactories are strategically located to serve key markets and reduce logistical challenges. For example, Gigafactory 1 in Nevada focuses on battery production, while Gigafactory 3 in Shanghai caters specifically to the Asian market. Explore Tesla’s global manufacturing strategy.

- Traditional Automakers: Many traditional automakers maintain large production facilities in their home countries and rely on extensive international supply chains for parts and materials. Companies like General Motors and Ford often have a more segmented approach, with different facilities dedicated to specific regions or vehicle models. This can lead to higher transportation costs and longer supply chains. Learn about traditional automotive manufacturing.

Supply Chain Models:

- Tesla: Tesla employs a vertically integrated supply chain model, meaning it controls a significant portion of its production processes and raw material sourcing. This model helps Tesla mitigate risks associated with supply chain disruptions and enhances its ability to innovate. Read about Tesla’s supply chain approach.

- Other Automakers: Many established automakers use a more traditional model with extensive outsourcing. While this can reduce initial capital expenditure, it also introduces greater dependency on external suppliers and can lead to longer lead times and potential quality inconsistencies.

Trends in Automotive Manufacturing Regarding Global Sourcing and Local Production

Several key trends are shaping the future of automotive manufacturing, reflecting broader shifts in the industry:

Shift Towards Local Production:

- Trend: An increasing number of automakers are adopting a more localized approach to manufacturing to reduce reliance on international supply chains and avoid tariffs. This trend is driven by the desire to improve supply chain resilience and respond more quickly to market demands.

- Impact on Tesla: Tesla’s expansion of its Gigafactories into new regions, such as Europe and Asia, is a direct response to this trend. By establishing local production facilities, Tesla can more effectively meet regional demand and mitigate risks associated with global supply chain disruptions. Explore local production trends.

Technological Innovations:

- Trend: Advances in manufacturing technology, including automation, artificial intelligence, and 3D printing, are transforming the automotive industry. These technologies enhance production efficiency, reduce costs, and enable more flexible manufacturing processes.

- Impact on Tesla: Tesla’s investment in cutting-edge manufacturing technologies, such as its advanced robotics and AI-driven production lines, exemplifies its commitment to innovation. This focus on technology not only improves production efficiency but also supports Tesla’s goal of maintaining high-quality standards. Read about technological innovations in manufacturing.

Where can you buy Tesla Parts from the Unofficial Channel?

Kylin EV Parts Ltd is located in Guangzhou, the hub of China’s automotive parts industry. Established in 2013, we focus on the supply chain of new energy automotive parts, providing brand solutions for entire vehicle series from a screw to exterior components, connecting the upstream and downstream supply chains, and forming strategic alliances with production factories through customization, alliance. Adhering to the principle of ensuring the quality of a component is equal to protecting the safety of a family.

In 2022, our international trade department was established, focusing on the integration of Tesla, VW, and BYD, as well as aftermarket modifications. As China’s premier B2B supplier, we offer a comprehensive service in integrating EV spare parts for numerous foreign sellers, both online and offline.

We extend a cordial invitation to collaborate with foreign dealers and explore OEM and ODM partnerships for our products. With our commitment to the most professional service, the highest quality products, and the most reasonable prices, we endeavor to provide unparalleled support.