Are All Tesla fenders aluminum?

Tesla, a pioneer in the electric vehicle revolution, has redefined the landscape of modern automotive engineering. Among its many innovations, the strategic use of aluminum in essential components stands out. Hoods, fenders, and doors—once made predominantly of steel—are now often crafted from this lightweight yet durable material. The benefits are clear: reduced weight, better energy efficiency, and enhanced performance. But here’s the lingering question: Are all Tesla fenders made from aluminum?

Not exactly. Tesla’s vehicle construction materials vary notably across models and components, offering a blend of lightweight aluminum and durable steel in key areas. For example, in the Model 3 and Model Y, the front doors, rear doors, and hood are crafted from aluminum, providing a lightweight frame. However, the front fenders, rear fenders, and tailgate shift to steel, offering strength and stability. The Model S follows a similar design ethos. Here too, aluminum dominates the hood, front fenders, and doors, while steel is reserved for the rear fenders and tailgate, ensuring a balance between weight and durability. And then there’s the Model X, which mirrors this pattern: aluminum is used for the hood, front fenders, and doors, while steel takes over for the rear fenders and tailgate. It’s a thoughtful approach that blends the best of both materials, balancing performance, safety, and weight distribution.

| Component | Model 3 | Model Y | Model S | Model X |

| Hood | Aluminum | Aluminum | Aluminum | Aluminum |

| Front Fenders | Iron | Iron | Aluminum | Aluminum |

| Rear Fenders | Iron | Iron | Iron | Iron |

| Front Doors | Aluminum | Aluminum | Aluminum | Aluminum |

| Rear Doors | Aluminum | Aluminum | Aluminum | Aluminum |

| Trunk Lid | Iron | Iron | Iron | Iron |

Material Comparison of Tesla Model 3, Model Y, Model S, and Model X

Tesla has consistently relied on aluminum for its original hoods across its vehicle lineup. This material choice helps reduce weight while maintaining durability and performance. However, when it comes to aftermarket hoods, the story changes. These replacements can vary greatly in terms of material composition and may not necessarily follow Tesla’s original choice of aluminum. In fact, some aftermarket options could be made from different metals or composites, which might affect both the weight and overall performance of the vehicle.

For those in the business of reselling Tesla parts, this is an important distinction to be aware of. The quality and material authenticity of the parts you’re sourcing are crucial for ensuring compatibility and maintaining the integrity of the vehicle’s design. Whether you’re offering replacement hoods or other components, understanding these material differences can make all the difference when advising customers or managing inventory.

1. Why Did Tesla Choose Aluminum for Hoods and Doors?

Tesla’s decision to use aluminum for hoods and doors is far from arbitrary—it’s a deliberate strategy that underscores the company’s commitment to innovation, performance, and sustainability. Aluminum offers a host of benefits that align perfectly with Tesla’s engineering goals, and the reasons behind this material choice are multifaceted:

1.1. Weight Reduction

Aluminum’s significant weight advantage over steel is one of the key reasons Tesla integrates it into critical components like doors, hoods, and other parts. In traditional car manufacturing, steel is often the material of choice, but aluminum offers a lighter alternative without sacrificing strength. By reducing the overall weight of the vehicle, Tesla achieves multiple benefits, particularly in the realm of energy efficiency.

With less mass to move, the electric vehicle demands less power to accelerate and maintain speed, which directly translates into a longer driving range per charge. In the world of electric cars, where maximizing range is paramount, this weight reduction is not just a bonus—it’s a vital component of Tesla’s performance strategy.

1.2. Enhanced Performance

The reduced weight of aluminum doesn’t just help extend the driving range—it also plays a pivotal role in enhancing the vehicle’s overall performance. With less mass to carry, Tesla’s electric vehicles experience quicker acceleration, sharper braking, and more responsive handling. These factors come together to elevate the driving experience, turning every journey into a dynamic interaction between driver and machine.

Tesla vehicles are known for their exhilarating performance, and the lightweight nature of aluminum is a key enabler of this reputation. Whether you’re accelerating on the highway or taking a tight corner, aluminum helps deliver that seamless, high-performance feel that sets Tesla apart from traditional combustion-engine cars.

1.3. Corrosion Resistance

Aluminum boasts a natural resistance to corrosion that far outpaces steel, making it an ideal choice for critical components like doors and hoods. Over time, this property helps preserve the vehicle’s structural integrity and aesthetic appeal, ensuring it remains in top condition despite exposure to the elements.

This is particularly valuable in regions that face harsh weather conditions, whether it’s the relentless salt on icy roads in winter or the searing heat and humidity of coastal areas. Aluminum’s resistance not only boosts durability but also minimizes maintenance needs, reducing the likelihood of rust or corrosion damage. Ultimately, this contributes to the vehicle’s longevity, allowing it to maintain its pristine appearance and reliable performance for years.

1.4. Sustainability

Aluminum stands out for its remarkable recyclability, and the impact of recycling it is nothing short of impressive. The process requires just 5% of the energy needed to produce new aluminum from raw materials, drastically cutting down on energy consumption. This significant reduction in energy use plays a pivotal role in lowering the overall carbon footprint of manufacturing.

By choosing aluminum for key vehicle components, Tesla isn’t just focusing on performance and weight reduction—it’s also making a powerful statement about sustainability. The use of aluminum helps minimize the environmental impact of production, reinforcing Tesla’s broader commitment to reducing emissions and promoting a greener, more sustainable automotive future.

1.5. Safety Improvements

Aluminum’s ability to absorb impact energy surpasses that of steel, making it an excellent choice for enhancing vehicle safety. In the event of a collision, aluminum’s energy-absorbing properties allow it to efficiently dissipate crash forces, reducing the impact on the vehicle’s occupants.

By integrating aluminum into key structural components, Tesla not only strengthens the vehicle’s durability but also improves its overall crashworthiness. This means that in the unfortunate event of an accident, the vehicle’s design is better equipped to protect those inside, contributing to a safer, more secure driving experience.

2. The Drawbacks of Tesla’s Use of Aluminum Hoods and Panels

While Tesla’s use of aluminum hoods and panels offers a range of advantages, it’s important to also consider the potential downsides. Despite the many benefits of aluminum, there are some trade-offs that can impact the vehicle’s overall performance and maintenance in certain situations. Let’s explore the key drawbacks associated with Tesla’s choice of aluminum:

2.1. Higher Manufacturing Costs

Aluminum, while offering numerous advantages, comes with a higher price tag compared to traditional steel. The production and processing of aluminum require more specialized techniques, including advanced shaping, forming, and joining methods. These processes demand specialized equipment and skilled expertise, which can add significant costs to the manufacturing process.

As a result, the use of aluminum in Tesla’s vehicles can increase production costs, ultimately impacting the final price that consumers pay. While these costs may be justified by the performance, safety, and sustainability benefits, they still represent a noteworthy factor in the vehicle’s overall price point.

2.2. Repair and Maintenance Challenges

While aluminum offers numerous benefits, it also presents unique challenges when it comes to repair and maintenance. Unlike steel, aluminum requires specialized tools and techniques for repairs, and not all body shops are equipped with the necessary expertise or equipment. This can limit repair options for Tesla owners, making it harder to find qualified service providers and potentially driving up the cost of repairs.

Moreover, aluminum is more susceptible to dents, scratches, and impacts compared to steel. This increased vulnerability means that minor collisions or even everyday wear and tear could result in more frequent repairs, contributing to higher long-term maintenance costs. As a result, while aluminum offers performance advantages, it can also create additional challenges for vehicle upkeep.

2.3. Limited Availability of Replacement Parts

The specialized nature of aluminum components means that replacement parts are not as widely available as their steel counterparts. This can create challenges when it comes time for repairs, as finding the right part might take longer, leading to extended wait times. For Tesla owners, this means that a vehicle requiring specific aluminum parts could face prolonged downtime, causing potential inconvenience.

In addition to the wait times, the cost of sourcing and replacing these parts can also be higher, further adding to the frustration. As the demand for aluminum components rises, the availability and pricing of replacement parts may continue to be an issue for those needing repairs down the line.

2.4. Susceptibility to Corrosion

While aluminum is generally more resistant to corrosion than steel, it’s not entirely immune. In harsh environments—such as areas with high levels of saltwater exposure or frequent use of road salts—aluminum components can still face corrosion over time. Despite its natural resistance, prolonged exposure to these elements can wear down the protective layers, leading to deterioration.

To counteract this, regular care and maintenance become critical. Keeping aluminum parts clean and protected from corrosive agents is essential to prolonging their lifespan and preserving their performance. While aluminum may resist corrosion better than steel in most cases, it’s not invincible, and attention to detail in vehicle upkeep remains a key factor in maintaining its durability.

2.5. Structural Integrity Concerns

Aluminum’s lighter weight and lower density, while beneficial for performance, can raise concerns about its structural integrity and rigidity when compared to steel. Although aluminum can be engineered to meet safety standards, its ability to withstand high-impact collisions may not always match the sheer strength of steel. In certain crash scenarios, there might be questions about whether aluminum can provide the same level of protection to occupants as its steel counterparts.

While Tesla takes great care in designing aluminum components for safety, the material’s inherent properties could present challenges in extreme conditions. In some cases, the trade-off for weight reduction might impact the vehicle’s ability to absorb and disperse impact energy as effectively as steel would.

3. Where Can You Find Tesla Repair Body Parts?

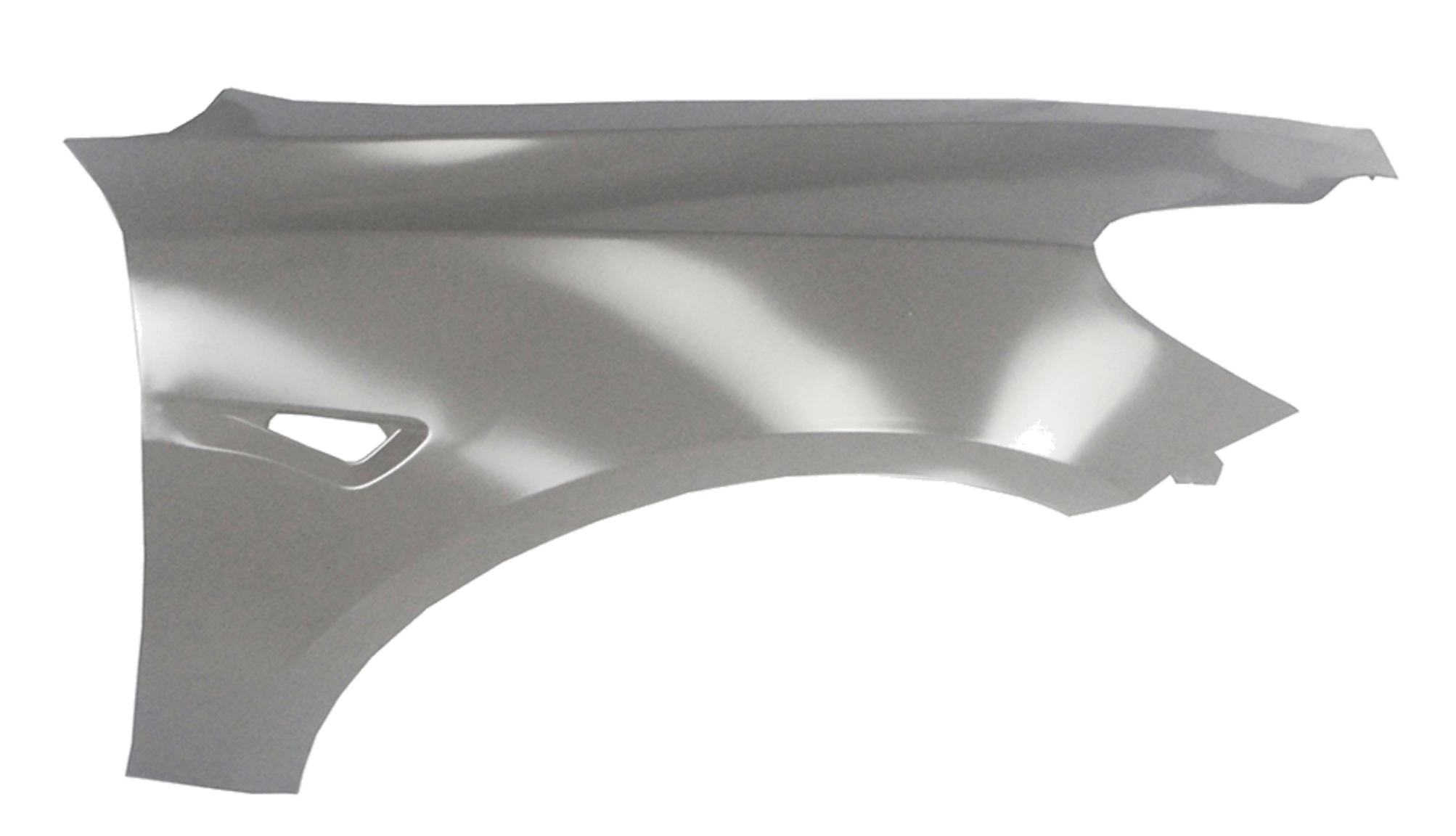

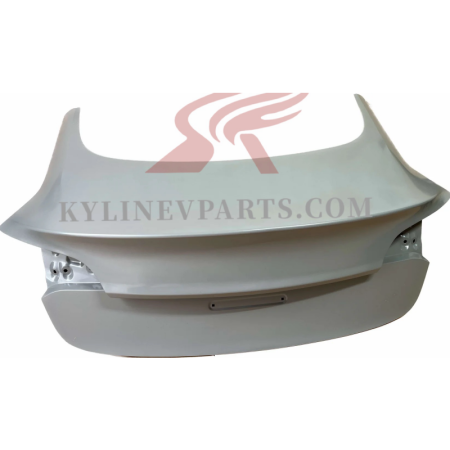

Given that aluminum car parts can be more challenging to repair, there’s a significant demand for new or intact Tesla aluminum parts, especially when it comes to components like hoods and fenders. But where can you source these parts? Finding the right replacement for a Tesla can be tricky, as availability often depends on the specific model and part in question. Whether you’re a Tesla owner in need of a repair or a reseller looking to stock parts, knowing where to look is essential.

3.1. Authorized Tesla Service Centers

One of the most reliable places to find genuine Tesla parts is through authorized Tesla Service Centers. These centers have direct access to OEM (Original Equipment Manufacturer) parts, ensuring that any replacements meet Tesla’s exact specifications and quality standards. When you choose to source your parts from an authorized service center, you’re guaranteed to receive components that are specifically designed for your vehicle, helping to maintain its performance, safety, and integrity.

3.2. Specialized Aftermarket Suppliers

A number of companies specialize in producing aftermarket parts designed specifically for Tesla vehicles. These suppliers often offer parts that match the quality of OEM components but at a more competitive price point. While this can be an attractive option for cost-conscious Tesla owners, it’s crucial to carefully vet these suppliers. Ensuring that their parts are both high-quality and fully compatible with your specific Tesla model is key to avoiding any issues down the road.

Choosing the right aftermarket part can be a balancing act—cost savings are important, but quality and compatibility should always come first.

3.3. Online Marketplaces

Online platforms like eBay, Amazon, and specialized automotive parts websites can serve as valuable resources for finding both new and used Tesla parts. These marketplaces offer a wide selection, but shopping online comes with its own set of considerations. It’s crucial to thoroughly check the seller’s ratings and reviews to gauge their reliability and the quality of the parts they offer. Taking the time to confirm that you’re purchasing the correct, high-quality parts will help you avoid compatibility issues and ensure you’re getting a product in good condition.

3.4. Salvage Yards and Recycled Parts Dealers

For those in search of used or refurbished Tesla parts, salvage yards and businesses specializing in recycled auto parts can offer a viable option. These establishments typically dismantle totaled or decommissioned Teslas, selling off the reusable components at a fraction of the cost of new parts. While this can be a more budget-friendly choice, it’s important to proceed with caution. Carefully inspecting the parts for any signs of damage or wear is essential to ensure they will still function properly and maintain the vehicle’s performance.

3.5. Tesla Owners’ Forums and Social Media Groups

Engaging with fellow Tesla owners through forums and social media groups can be an excellent way to track down parts. These communities are full of members who often share their experiences with different suppliers and can provide recommendations on where to find quality parts at competitive prices. By tapping into these networks, you can gain valuable insights, hear about others’ successes and challenges, and avoid potential pitfalls when sourcing replacement parts. It’s like having a support group that helps you navigate the often tricky world of auto parts.

Where to Buy Tesla Fenders?

Kylin EV Parts Ltd is located in Guangzhou, the hub of China’s automotive parts industry. Established in 2013, we focus on the supply chain of new energy automotive parts, providing brand solutions for entire vehicle series from a screw to exterior components, connecting the upstream and downstream supply chains, and forming strategic alliances with production factories through customization, alliance. Adhering to the principle of ensuring the quality of a component is equal to protecting the safety of a family.

In 2022, our international trade department was established, focusing on the integration of Tesla, VW, and BYD, as well as aftermarket modifications. As China’s premier B2B supplier, we offer a comprehensive service in integrating EV spare parts for numerous foreign sellers, both online and offline.

We extend a cordial invitation to collaborate with foreign dealers and explore OEM and ODM partnerships for our products. With our commitment to the most professional service, the highest quality products, and the most reasonable prices, we endeavor to provide unparalleled support.