How Thick Is the Tesla Bumper Beam?

The bumper beam is a crucial component in vehicle safety, designed to absorb impact forces and dissipate energy during a collision. Traditionally, these beams were crafted from high-strength steel, offering robust durability and cost-effectiveness. However, the downside of steel is its weight, which can affect overall vehicle performance and efficiency. As the demand for lighter, more fuel-efficient cars grows, high-strength steel has proven to be inadequate, prompting the shift toward alternative materials. Composite materials, celebrated for their combination of lightness and exceptional strength, have emerged as the new standard, providing a perfect balance between safety and performance without the added weight.

1. Are Tesla bumpers made of metal? Iron or Aluminum?

Like most modern vehicles, Tesla bumpers feature a plastic outer layer, designed mainly for aesthetic appeal and to enhance aerodynamics. Beneath this plastic cover and the energy-absorbing material lies a sturdy metal beam that forms the core of the bumper, providing essential strength and impact resistance. This metal beam is typically made of aluminum, known for its balance of lightweight properties and durability.

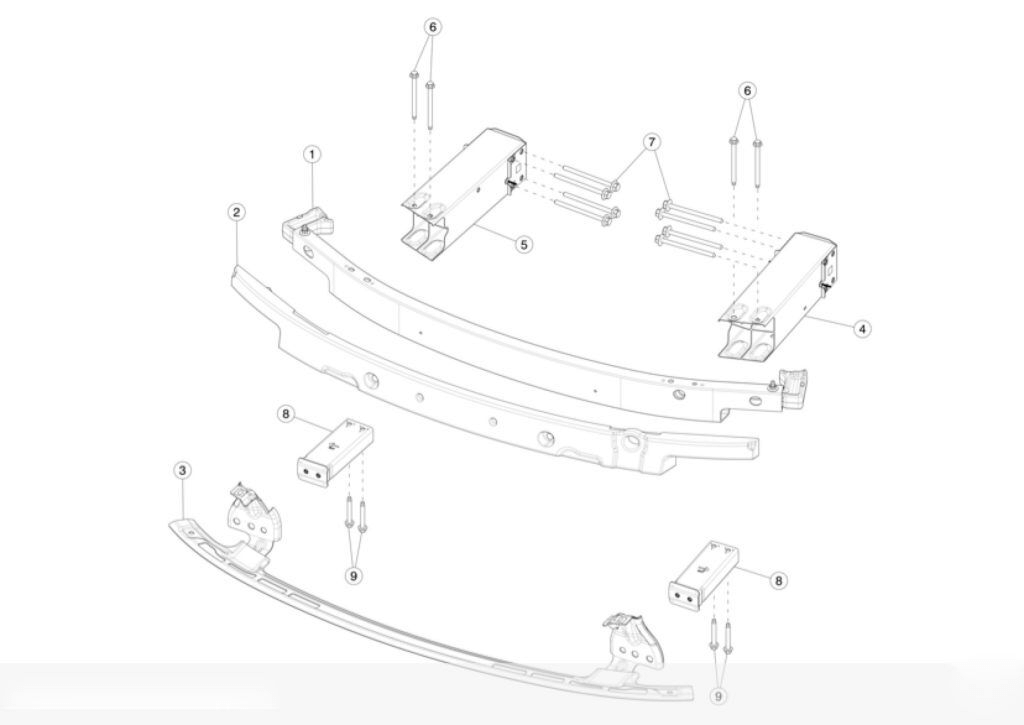

| Parts | Items | OE Number | Material | Link |

| Parts 1 | MDY ASY FR Bumper Beam | 1487601-00-E | Aluminum | |

| Parts 2 | MDY FR Bumper Beam Foam | 1487605-00-A | Foam | |

| Parts 3 | MDY ASY Ankle Catcher | 1505433-00-A | Aluminum | |

| Parts 4 | MDY ASY Crush Can LH | 1487461-00-D | Aluminum | |

| Parts 5 | MDY ASY Crush Can RH | 1487462-00-D | Aluminum | |

| Parts 6 | MDY Screw Bolt | 1111151-00-A | Iron | |

| Parts 7 | MDY Screw Bolt | 1120775-00-A | Iron | |

| Parts 8 | MDY Front Bumper Bracket | 1109193-00-C | Aluminum | |

| Parts 9 | MDY Screw Bolt | 1135014-00-A | Iron |

In the Tesla Model Y parts catalog, part 2, labeled “MDY FR bumper beam,” is the only component made of foam, while all other parts are made from metal. This indicates that the Tesla front bumper beam is, in fact, constructed from aluminum.

2. AL6082-T4 Extrusions vs. AL6063-T4 Extrusions

Both AL6063-T4 and AL6082-T4 are aluminum alloys from the 6000 series, known for their excellent formability, weldability, and machinability, along with moderate to high strength. The “T4” temper signifies that these alloys have undergone solution heat treatment and natural aging to achieve a stable condition. While they share these foundational properties, there are key differences in their chemical composition, mechanical properties, and common applications.

Chemical Composition:

- 6063 Alloy:Mainly composed of aluminum, magnesium, and silicon. This alloy is known for its superior surface finish and is commonly used in architectural applications, especially for extrusions.

- 6082 Alloy:Also made from aluminum, magnesium, and silicon, but with different proportions. It includes a small amount of manganese, which helps refine the grain structure and enhances the alloy’s strength.

Mechanical Properties:

- 6063-T4:Known for its excellent surface finish and anodizing properties, 6063-T4 provides good strength but falls short of the strength offered by 6082. It is particularly suited for applications where appearance is a key consideration, such as window frames and doors.

- 6082-T4:Provides higher strength than 6063, making it better suited for structural applications. It is commonly used in high-stress environments, such as trusses, bridges, and cranes, where enhanced durability is required.

Preferred Applications:

- 6063 Alloy:Frequently used in architectural applications, including building profiles, structures, irrigation pipes, and extrusions for window frames, door frames, and sign frames, where a smooth surface finish is crucial.

- 6082 Alloy:Selected for applications that require higher strength and durability. It is commonly used in transportation, bridges, and other high-stress environments. Additionally, its enhanced strength makes it ideal for manufacturing products like beer barrels and milk churns.

Although both 6063-T4 and 6082-T4 are versatile and widely used aluminum alloys with similar base elements, the choice between them depends largely on the specific requirements of the application. If higher strength and toughness are essential, 6082-T4 is the preferred option. However, for applications where aesthetics and a smooth surface finish are critical, 6063-T4 stands out due to its excellent formability, making it ideal for architectural uses.

| Property | AL6063-T4 | AL6082-T4 |

| Strength | Moderate strength alloy | High strength alloy |

| Formability | Excellent formability for extrusion | Moderate formability for extrusion |

| Machinability | Good | Good |

| Corrosion Resistance | Good corrosion resistance | Excellent corrosion resistance |

| Typical Uses | Architectural applications, window frames | Structural applications, high-stress areas |

3. Tesla Bumper Beam Aftermarket Accessories Made with 6063-T4

Tesla’s original front and rear bumper beams are crafted from AL6082-T4 aluminum alloy, known for its exceptional strength and durability. However, many aftermarket manufacturers choose AL6063-T4 due to its lower cost and easier processing. While AL6082-T4 is more expensive, AL6063-T4 still provides excellent crash performance. Premium automakers like BMW, Mercedes-Benz, and Audi use AL6082-T4 in their original bumper beams to meet strict crash test standards, but AL6063-T4 also offers strong crash resistance. It’s crucial for manufacturers to be transparent with consumers about the materials used in aftermarket products and their crash performance to ensure informed purchasing decisions.

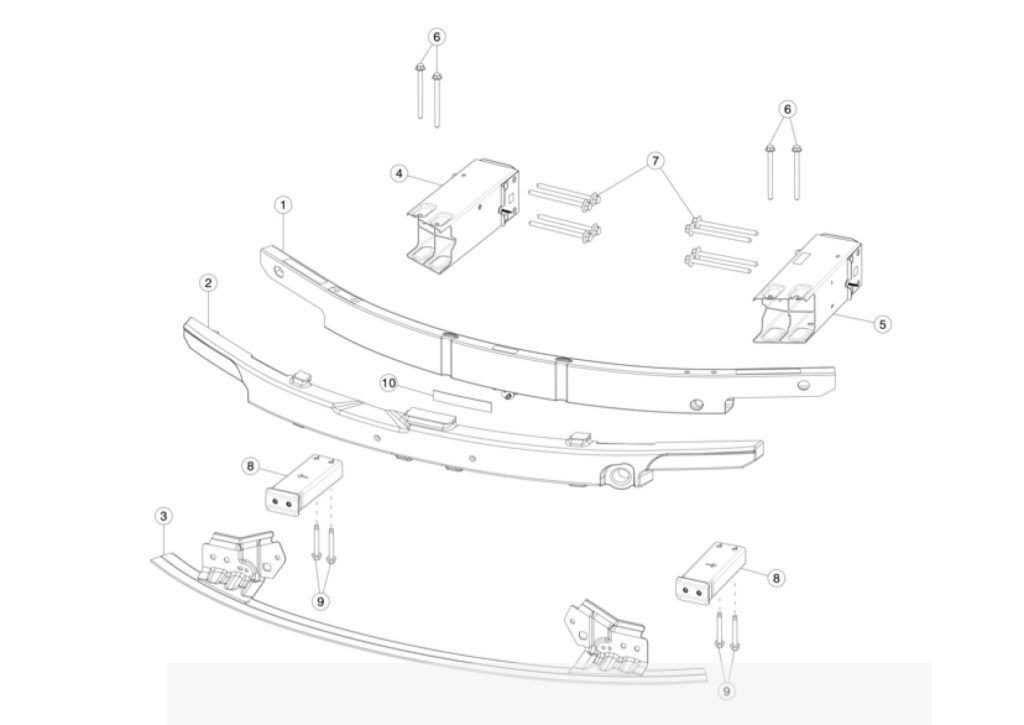

| Parts | Items | OE Number | Material | Link |

| Parts 1 | MD3 ASY, FR Bumper Beam – Extrusion 2016-2021 | 110466799J | Aluminum | Check |

| Parts 1 | MD3 ASY, FR Bumper Beam – Extrusion 2021+ | 1104667-00-K | Aluminum | Check |

| Parts 2 | MD3 FR Bumper Beam Foam | 1104669-00-F | Foam | |

| Parts 2 | MD3 FR Bumper Beam Foam 2021 | 1104669-CN-G | Foam | |

| Parts 3 | MD3 ASY Ankle Catcher | 1084894-00-B | Aluminum | Check |

| Parts 4 | MD3 ASY Crush Can LH | 1088148-00-G | Aluminum | Check |

| Parts 5 | MD3 ASY Crush Can RH | 1088149-00-G | Aluminum | Check |

| Parts 6 | BOLT,HF,M10X130,STL[109],ZNFL,MAT | 1446114-00-B | Iron | |

| Parts 7 | BOLT,HF,M10-1.5X157,[149],G0110,PC | 1552976-00-A | Iron | |

| Parts 8 | MD3/Y Front Bumper Bracket | 1109193-00-C | Aluminum | Check |

| Parts 9 | BOLT, HF, M10X1.5X75.75, STL[109], ZN | 1135014-00-A | Iron | |

| Parts 10 | BUMPER DOUBLE SIDED TAPE | 1455921-00-A | ||

| BRUSH CLIP, 6.5X33, PA66,B | 1526009-00-A |

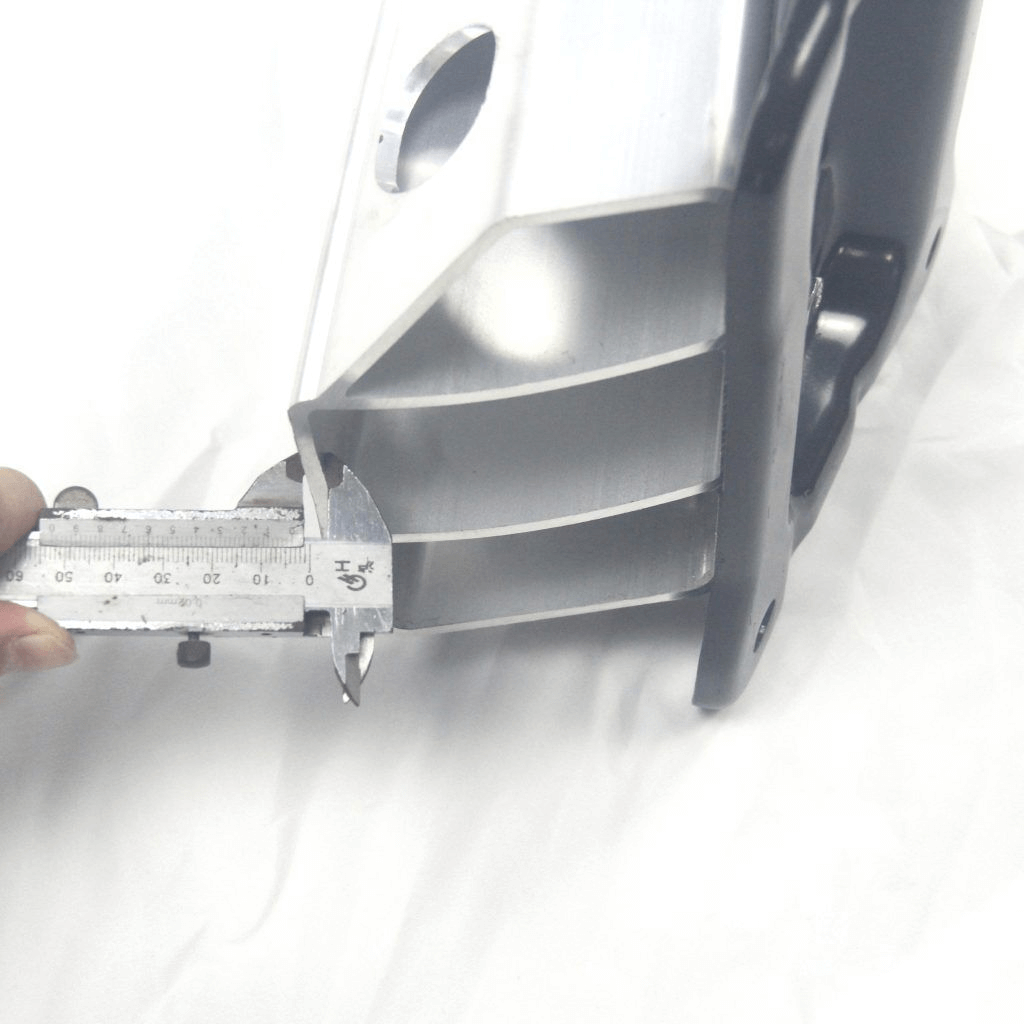

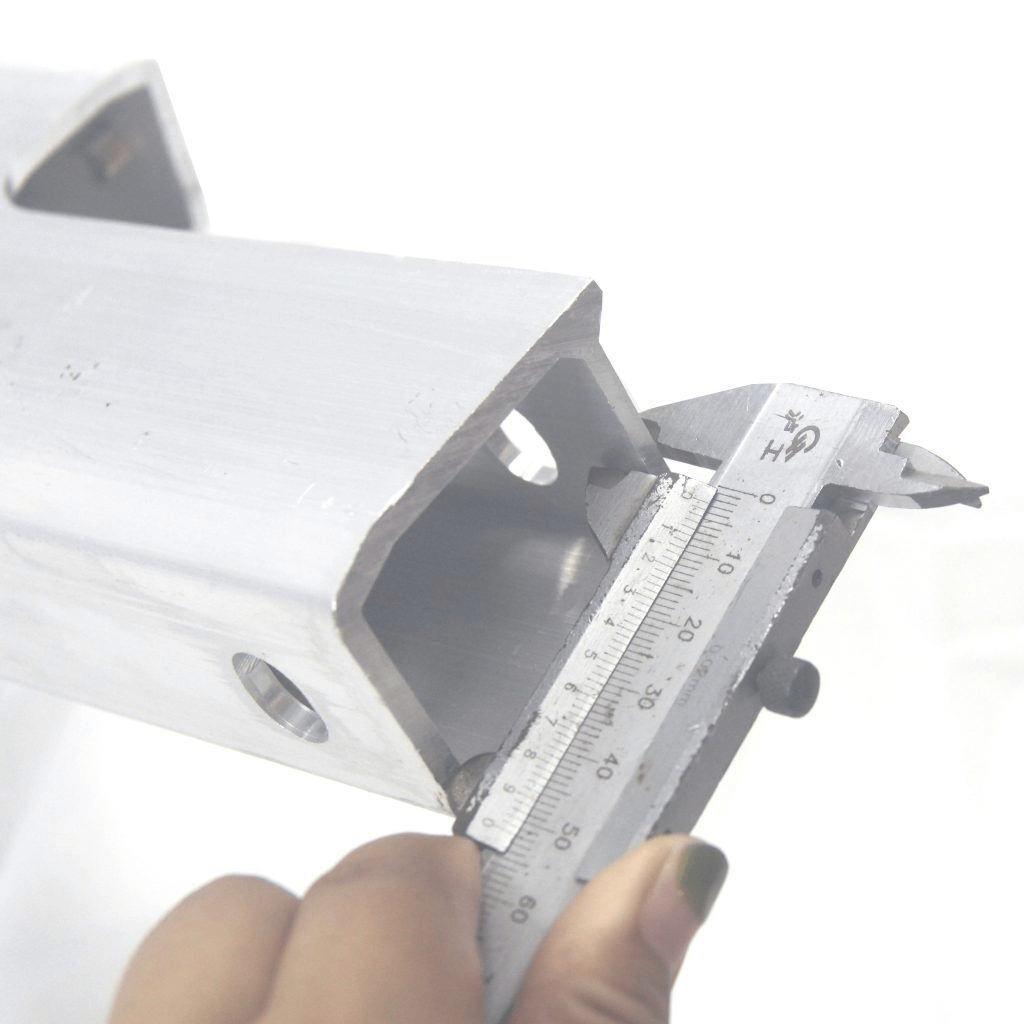

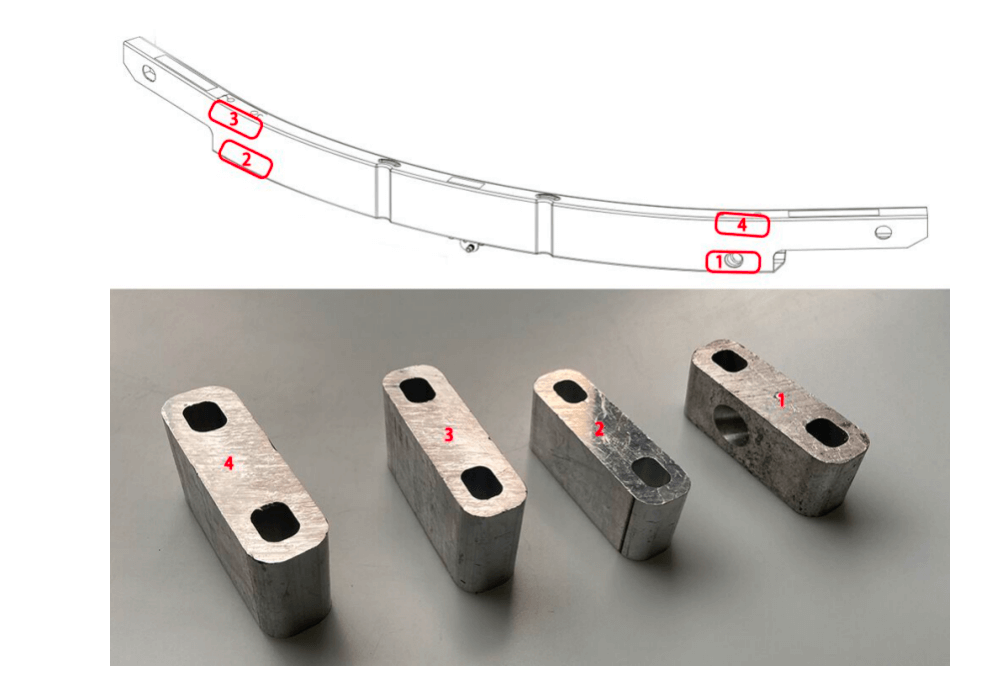

4. Bumper Beam Thickness

Unlike many suppliers who cut corners by reducing material quality and thickness, we ensure our product meets the original specifications. This commitment to maintaining thickness is crucial for durability and safety, similar to Tesla’s Model 3 and Model Y hoods.

When comparing Tesla’s front and rear bumper beams, you’ll notice that many cheaper alternatives on the market are thinner than the original factory beams, with some measuring less than 2mm in thickness. Our bumper beam, however, adheres to the original factory thickness, ensuring it offers the same level of strength, durability, and safety.

5. What is the circle on the Tesla bumper?

The circle on the Tesla bumper is a tow hook cover. It conceals the access point where a tow hook or towing eye can be attached to the vehicle. This feature is specifically designed for emergency situations, allowing the car to be safely towed if it becomes disabled or stuck.

When sourcing Tesla bumpers in China, you’ll find a surprising variety of prices, ranging from as low as $15 to more than $30. This price gap is entirely normal, but it’s an indicator of the varying quality of the products. Some bumpers are noticeably thinner—sometimes less than 2mm thick—compared to the factory standard of 4mm. And that’s not all: the internal aluminum blocks, which are originally four, are often reduced to just one, typically located around the towing hole. This reduction in both material and production complexity drastically cuts costs, leading to those enticingly low prices.

But how can you tell if you’re getting the real deal? It’s simple. Just ask your supplier for the bumper’s weight. A quick comparison will easily reveal whether you’re getting a product that meets the original factory standards or one that’s been downgraded for cost-saving reasons. It’s all in the details.

The trade of Tesla parts is filled with intriguing dynamics, whether you’re involved in the Tesla business, have a keen interest in sourcing these parts, or are a trader or importer collaborating with Chinese factories. If you’re navigating the often-complex procurement process and facing obstacles, we’d love to connect and offer our expertise. Let us help streamline your sourcing experience, making it smoother, more efficient, and ultimately more successful.

Where to Buy Tesla Parts and Accessories ?

Kylin EV Parts Ltd is located in Guangzhou, the hub of China’s automotive parts industry. Established in 2013, we focus on the supply chain of new energy automotive parts, providing brand solutions for entire vehicle series from a screw to exterior components, connecting the upstream and downstream supply chains, and forming strategic alliances with production factories through customization, alliance. Adhering to the principle of ensuring the quality of a component is equal to protecting the safety of a family.

In 2022, our international trade department was established, focusing on the integration of Tesla, VW, and BYD, as well as aftermarket modifications. As China’s premier B2B supplier, we offer a comprehensive service in integrating EV spare parts for numerous foreign sellers, both online and offline.

We extend a cordial invitation to collaborate with foreign dealers and explore OEM and ODM partnerships for our products. With our commitment to the most professional service, the highest quality products, and the most reasonable prices, we endeavor to provide unparalleled support.