Tesla Dealership Parts: How to Get a Reliable Channel and Build a Scalable B2B Supply Program

If you are trying to source tesla dealership parts for a workshop, a distributor program, or a repair network, the problem you are facing is usually not pricing, not speed, and not even supplier effort, because the real problem is that Tesla dealership parts were never designed to behave like an open wholesale product channel, which means you can spend months looking for a stable route and still end up with small quantities, inconsistent access, and unclear responsibility once the parts are installed.

This article practically solves that problem by mapping what Tesla dealership parts really are, why the Tesla service ecosystem stays closed, why volume sourcing through OEM routes in China rarely becomes repeatable distribution, and how to build a compliant alternative using aftermarket service parts that can scale without creating uncontrolled risk, unstable fitment, or long-term reputational damage for your business.

What Tesla Dealership Parts Really Mean in the Real World

In legacy automakers, dealership parts usually sit inside a dealer network that acts as a regional distribution node, so dealership parts can circulate through multi-tier channels and still remain stable, but Tesla does not operate a conventional dealer system, which is why tesla dealership parts in practice are tied to the internal supply and repair workflow of Tesla Service Centers, and that internal system was created to complete Tesla’s own repair loop rather than to support third-party wholesale distribution at scale.

Once you accept that structural difference, Tesla dealership parts stop being a mystery and become a boundary, because it tells you what Tesla will keep inside the closed loop, and it also tells you where you should not build your long-term inventory strategy if you want repeatable supply and predictable delivery for B2B customers.

Key Takeaway on Tesla Dealership Parts and Channel Stability

The most reliable way to stop supply volatility is to treat Tesla dealership parts as a closed-loop reference, then build your B2B program outside that loop with engineered aftermarket service parts that are verifiable, traceable, and scalable, because the closed loop is optimized for Tesla’s risk containment rather than your distribution growth.

Why Tesla Controls Tesla Dealership Parts More Strictly Than Traditional Brands

Many buyers assume Tesla restricts Tesla dealership parts mainly to protect margins. Still, the deeper driver is safety liability, because when a part is installed incorrectly, or a repair process is performed without standardized training and diagnostic discipline, the risk chain can escalate into incidents that attract regulatory and public scrutiny. The accountability typically returns to the automaker rather than a small third-party workshop, which is why Tesla’s control over Tesla dealership parts is fundamentally a risk-management decision that protects Tesla’s minimum viable unit of traceable safety closure.

Safety Liability: The Practical Risk Chain Behind Tesla Dealership Parts Control

The risk chain that matters is operationally simple but financially massive, because an incorrect repair can trigger a fault, the fault can develop into a critical event, and the reputational and legal exposure then targets the vehicle brand, which means Tesla has strong incentives to keep tesla dealership parts, diagnostics access, calibration workflows, and authorization rules within a controlled environment that Tesla can audit and trace.

EV Architecture Turns Parts into System Dependencies, Not Isolated Swaps

EV platforms amplify risk into system-level coupling across high-voltage components, battery packs, thermal management, airbags, sensors, control modules, and ADAS calibration linked with software behavior, which means a component is often a dependency inside a safety envelope rather than an isolated mechanical replacement, and that is a major reason tesla dealership parts behaves like a controlled safety pipeline rather than a standard wholesale commodity channel.

Why Tesla Gates Parts, Diagnostics, Supply, and Authorization as One Package

Tesla’s practical toolkit for risk containment is to gate parts access, gate diagnostics access, gate supply-chain visibility, and gate authorization processes, because the smallest manageable unit is a closed loop in which Tesla can trace what was installed, how it was installed, and whether calibration steps were performed correctly, which is why tesla dealership parts cannot be treated as an open inventory pool in the same way that dealership parts can be treated in many legacy ecosystems.

Why Toyota and BMW Dealership Parts Circulate, While Tesla Dealership Parts Do Not

Traditional automakers built dealership systems that function as both service and distribution networks, where parts operate as products that can flow through layered channels and the industry has long-established standards and shared accountability mechanisms, while Tesla service centers function more like safety execution nodes where tesla dealership parts is coupled to diagnostics, calibration, and software-linked behavior, so the same phrase dealership parts describes a commodity channel in one world and a controlled safety loop in the other world.

Simple Comparison That Helps You Choose the Right Sourcing Strategy

Legacy dealership parts can be operationalized as commercial inventory with distribution playbooks, while Tesla dealership parts are embedded in a safety and liability system, so your sourcing strategy should assume structural constraints on OEM-channel scale and then plan your volume program around engineered aftermarket solutions that can be validated and repeated.

The Practical Problem You Need to Solve: Stable Supply, Clear Fitment, and Scalable B2B Delivery

If your business depends on fulfilling repeated orders, supporting workshop installs, and reducing aftersales disputes, then the sourcing model has to deliver stable availability, clear fitment boundaries, and accountable quality, and that is exactly where chasing tesla dealership parts as your main foundation becomes fragile, because even when you can obtain tesla dealership parts in small quantities, the route is often inconsistent, non-repeatable, and difficult to scale when your demand grows.

The scalable solution is to build a high-quality aftermarket service-parts program that is compliant, traceable, and engineered around repeatable fitment boundaries, because this approach solves the same real-world need that many buyers associate with Tesla dealership parts, while avoiding the structural bottlenecks of the OEM service loop.

A Common Misunderstanding: Tesla OEM Suppliers in China Exist, but OEM Control Limits Wholesale Scale

It is true that a significant portion of Tesla’s OEM supply chain is located in China. Still, that fact does not automatically create a scalable wholesale route, because OEM-controlled ecosystems often enforce strict controls over part flow, batch allocation, and channel permissions, which means access can exist through narrow routes. Still, volume continuity is difficult to guarantee, and in real operations, that often results in small-quantity availability rather than the repeatable supply that distributors expect when they build an inventory program around Tesla dealership parts.

For B2B buyers, the operational requirement is not whether Tesla dealership parts can be obtained occasionally, because occasional access does not equal program reliability, and reliability is what your downstream customers will judge you on when you commit to lead times, warranty handling, and repeat purchases.

What You Should Require From Any Tesla Dealership Parts Supplier Alternative

If you are evaluating a Tesla dealership parts supplier or an alternative program, you should require stable batching, clear compatibility boundaries, accountable QC, and traceable after-sales handling, because these requirements reduce disputes and prevent costly returns, and these requirements also allow you to scale without betting your reputation on unpredictable OEM access.

The Scalable Direction: Aftermarket Service Parts Built for Repeatable B2B Operations

The long-term B2B model is not the one that tries to claim the most official channel language, because tesla dealership parts is structurally closed, but the one that delivers controllable outcomes and operational certainty, which is why mature aftermarket programs focus on part-number mapping discipline, compatibility boundary clarity, and stable production consistency that makes the buyer confident that each batch will behave like the previous batch.

What Makes Aftermarket Work When Tesla Dealership Parts Do Not Scale

A mature aftermarket service-parts program is engineered around predictable fitment and known failure-mode replacement, which means it must provide clear Part Number mapping logic, explicit vehicle-year and variant boundaries, explainable replacement rationale, and stable batching rather than opportunistic sourcing, and once these elements are present, the business value becomes the certainty you originally hoped to achieve through tesla dealership parts, but in a form that can actually be replicated across customers and regions.

Categories That Usually Fit a Responsible Aftermarket Program

While category selection depends on your local market and repair capabilities, the most scalable programs typically focus on high-frequency repair needs with clear failure modes and engineering-controllable risk, because this is where you can build repeatable installation outcomes and predictable after-sales handling, and this is also where your inventory planning becomes viable without needing to rely on Tesla dealership parts availability that fluctuates.

Why Repair Networks and Distributors Shift Toward Stable Aftermarket Partners

Professional buyers eventually optimize for controllable risk, predictable supply, and repeatable delivery, because they do not want to bet their entire operation on bypassing Tesla’s closed loop, and they also do not want to fight recurring disputes caused by unclear fitment and unstable batching, which is why more organizations treat tesla dealership parts as a boundary reference while building their commercial inventory around stable aftermarket partners who can provide mapping logic, fitment clarity, and consistent production discipline.

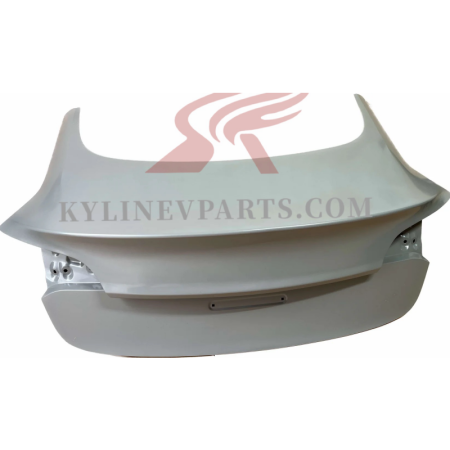

How Kylin EV Parts Provides a Practical Alternative to Tesla Dealership Parts for B2B Buyers

Kylin EV Parts focuses on high-quality Tesla aftermarket service parts for professional B2B buyers who need clarity and repeatability, and we provide clear Part Number mapping logic and explicit fitment boundaries while also defining which categories are suitable for aftermarket solutions and which categories should be avoided in order to respect safety red lines, and our aftermarket manufacturing partners also serve top-tier Chinese EV brands such as Xiaomi and XPeng, which supports stronger quality systems, process consistency, and stable batching that B2B buyers typically require when they build a long-term supply relationship that does not depend on unpredictable tesla dealership parts access.

Implementation Checklist: How to Build Your Program Without Depending on Tesla Dealership Parts

If your current plan depends heavily on tesla dealership parts, you can reduce operational risk by building an alternative program with three non-negotiables, which include a documented mapping logic for the parts you sell, a published fitment boundary framework that reduces misunderstanding, and a stable batching process that is supported by consistent QC and traceable aftersales handling, and these three elements together give you the same commercial benefits that many buyers expect from tesla dealership parts, but in a structure that supports scale.

Step 1: Replace Channel Dependency With Mapping Discipline

The fastest path to fewer disputes is to build a clear mapping between common Part Numbers and the aftermarket service part you supply, because this makes ordering and verification easier for B2B buyers and workshop technicians, and it also reduces the temptation to rely on Tesla dealership parts as the only source of truth.

Step 2: Publish Fitment Boundaries That Technicians Can Follow

Fitment clarity should be expressed in vehicle model, production year, and relevant variants, because technicians need operational boundaries rather than broad claims, and when you provide this clarity, you reduce returns and installation errors, which is a practical advantage that many buyers chase when they seek Tesla dealership parts but can often achieve more reliably with a disciplined aftermarket program.

Step 3: Build Stable Batching and QC That Supports Repeat Orders

Stable batching matters because repeat orders are the foundation of B2B business, and once you can deliver consistent batches with controlled QC, your customers stop treating your supply as experimental and start treating it as a program, which is the same business outcome many people hope to reach through Tesla dealership parts, but achieved with a channel that is designed to scale.

Conclusion: Tesla Dealership Parts Is a Boundary Reference, and the Scalable Answer Is a Controlled Aftermarket Program

Studying Tesla dealership parts is useful because it reveals Tesla’s structure and liability logic, but building your distribution foundation on tesla dealership parts will usually trap you in instability, non-repeatable sourcing, and scaling ceilings, and the mature path is to use system understanding to build a compliant and controllable aftermarket service-parts program that meets persistent repair demand through stable supply, clear fitment boundaries, and accountable delivery, which is how professional buyers get the certainty they need without depending on a channel that was never built for open wholesale scale.